Flanging The Last Boiler Plate – Easy Now

Having learned the hard way, on-the-job, how not to form copper boiler plates forming the last boiler plate – the ThroatPlate was comparatively easy.

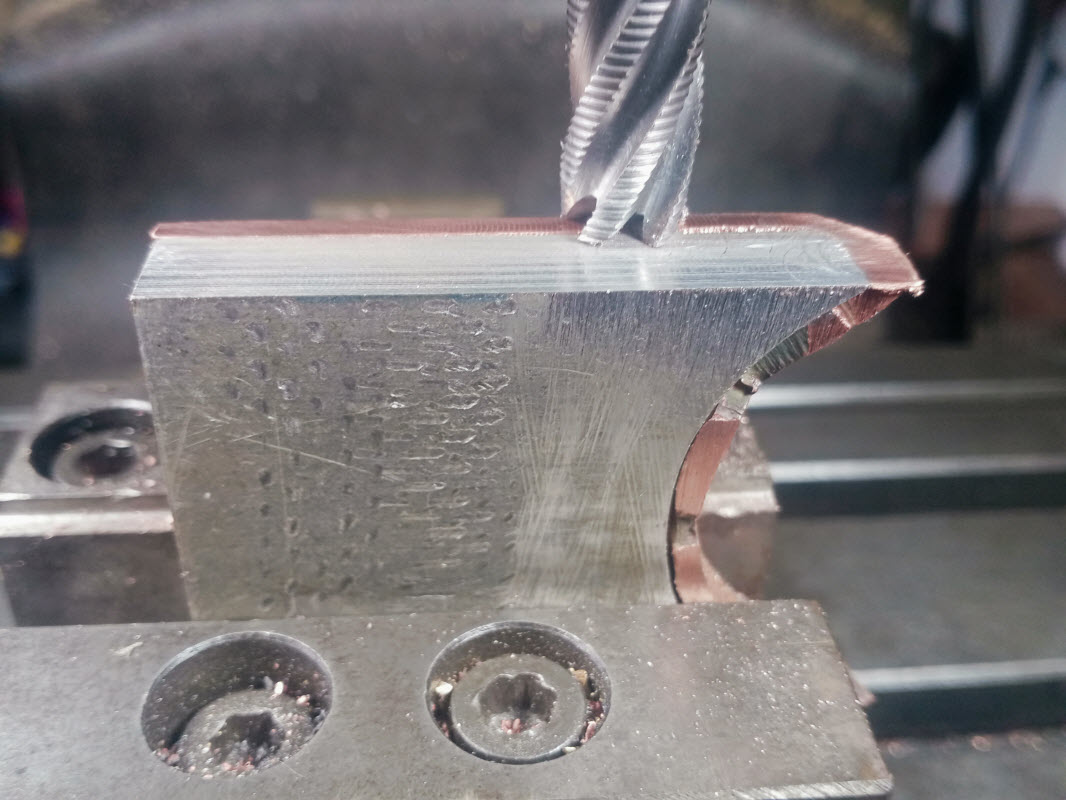

The first job was to make the former, this time machined from aluminium.

Forming The ThroatPlate – Method

The photo below shows the ‘brute-force’ method of flange-forming the ThroatPlate for the boiler. The copper sheet is squeezed in the bench vice jaws between the aluminium former and an aluminium backing plate. The copper is formed using the round steel disk as a dolly under heavy blows from the 3 1/2 lb hammer.

The Gallery below shows the various stages of forming the ThroatPlate – not necessarily on chronological order, but you’ll get the idea. Of course the copper sheet was repeatedly annealed.

Next it was time for the copper boiler plate, now having the flange formed, to be trimmed to final size on the outside edges. The sides were trimmed on the milling machine and the curved flange neatened by hand filing.

The next photo displays the finished ThroatPlate fitted up to the Boiler.