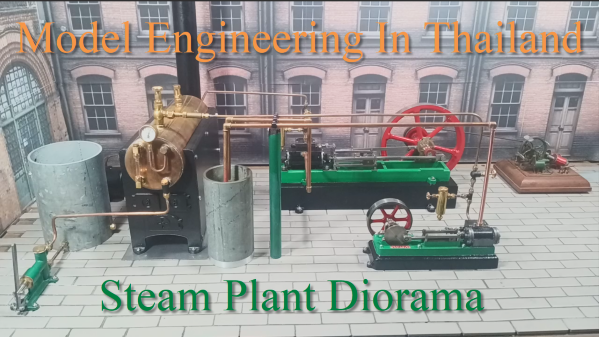

Welcome To The Model Engineering In Thailand And South East Asia Website

Model Engineering in Thailand is alive and well, even if there aren’t many of us. I know of three people making engineering models in Thailand including myself and other people make CNC controlled machine tools, off-road buggies etc.

Some Photos Of Model Engineering In Thailand Projects

Just hover over any image to stop the slideshow.

Get Your Photo(s) In The Slideshow

Just send me your photo(s) and I’ll add them to the slideshow above.

Our Members

There are now over 40 people in Thailand who have hobby workshops and who have joined the Announcement List. (See bottom of page)

If anyone reading this is also making engineering models, or is involved or just interested in metalworking or home workshop then please step forward and identify yourself. The more people interact of the website the greater will be the accumulated knowledge of resources, methods and ideas.

What Is Model Engineering?

Model Engineering I believe started in the U.K. around the early twenties. It is taken to mean making models of engineering machines in a home workshop. The models may be static or moving. Often they are miniatures of the full size engineering machine.

What kind of machines are modeled by Model Engineers? Here is a short list of some of the most popular models but really there is no limit to what may be modeled:-

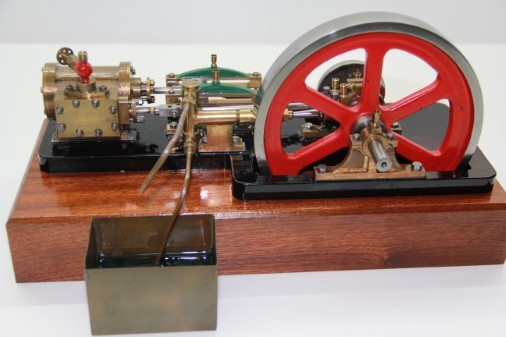

- Steam Engines (Locomotives)

- Steam Engines (Static – Mill Engines, Marine Engines)

- Steam Traction Engines

- Internal Combustion Engines

- Machine Tools

- Clocks

Also the Model Engineer often makes workshop equipment and accessories.

What Is Different About Model Engineering In Thailand?

Model Engineers in the U.K. are very well catered for. There are magazines, clubs and societies and a plethora of shops and businesses selling suitable machine tools, castings, kits and materials aimed specifically at the Model Engineering hobbyist. It is a huge industry.

In contrast there are only a handful of people in Thailand practicing Model Engineering and there is no specialist support from the trade. ie no model engineering materials or workshop equipment suppliers.

That is not to say that you can’t buy tools, workshop machinery and materials, because you can. These are the main sectors supported by suppliers:-

- Construction. Houses, factories and offices all need tools and raw materials.

- Manufacturing. Thailand has a reasonably sized manufacturing industry. Toyota motors for example in Bangkok is supported by dozens if not hundreds of smaller manufacturing businesses and they all need machine tools, tools and materials.

- Agriculture and automobiles. General fixing things. The Thais do not have the ‘throw away and buy new’ attitude, rather the ‘make do and mend’. There is a huge amount of agricultural machinery in Thailand and it all needs maintenance and repairs. There is a strong repair industry from replacing bearings in pumps to rewinding electric motors and rebuilding automobile engines.

In Bangkok if you want to buy big workshop equipment there is plenty of choice. From CNC Machining Centres to Wire Erosion Machines it’s all available. There is plenty of steel, brass, bronze and other metals available.

But it’s all geared to the sectors I mentioned above. The machine tools will be big as will the sections of metals.

There are no small bright mild steel sections, no small-scale foundries. If you want that kind of thing you will probably have import it from U.K. (At great expense)

My Early Model Engineering Years In U.K.

Setting up and running my model engineering workshop here in Pakchong (Pak Chong), Thailand reminds me of my first introduction to model engineering in the UK many, many years ago.

I was about 15 years old and still in school when Dad bought me my first lathe.

It was a worn-out 3 1/2″ Drummond flat bed lathe. The headstock bearing were so worn that you could lift the spindle off the bottom of the bearings by hand. It was only kept in place by self-weight, so cuts had to be light or you lifted the spindle.

The leadscrew was so worn at the headstock end you could actually see with the naked eye the difference in thickness of the screw thread at both ends of it.

These was no topslide and the tool holder was made up of plates of steel welded together and eventually the welds failed.

Still being school I had little money and couldn’t afford to buy all the drills, reamers, taps and dies etc that you need for real model engineering. Most of the drilling was done in the lathe with the workpiece supported by the tailstock barrel. I eventually bought a drill-press holder for the Black and Decker hand drill.

I made my own cutting tools out of old carbon steel hand files.

Despite all this I managed to make a 3 1/2″ gauge rolling Juliet tank engine chassis. (Rolling because it had wheels. No cylinders or valve gear)

It was make do and improvise.

Model Engineering (for me) in Thailand is like that. Not because of lack of money (although the very high cost of importing from the UK does make it almost prohibitive) but because of lack of suitable suppliers. (Or more correctly lack of knowing where suitable supplies are and this is being put right now through the Resources Section of this website)

Typical Model Engineering Items Available And Unavailable In Pakchong (Pak Chong), Thailand

A few simple things that I need right now that I can’t get in Pakchong (Pak Chong):-

- Tailstock lathe centre.

- Dividers for marking out. (Now located!)

- Certain size drills.

- A bandsaw at a reasonable price.

- Small section steel (BMS) and brass).

- Optical Centre Punch.

- Silver steel.

- Any kind of metal-working precision instrument. (e.g. engineer’s square, protractor)

A few things you can get in Pakchong (Pak Chong):-

- Almost any type and size of welding machine and equipment.

- Disk type cut-off machines.

- Almost any size of steel, bronze, cast iron and brass. (Large sizes)

- Electric hand tools such as jigsaws, drills etc.

- Normal sizes of drill bits.

- Normal type of hand tools as found in Do-It-Yourself superstores in the U.K.

It’s all a bit upsetting because I have a well fitted-out model-engineering workshop in the U.K. but it’s just too expensive and difficult to have everything shipped out to me.

Update: When I retired to Thailand I bought my entire UK model engineering workshop with me in a container.

Finding Suppliers and Resources For The Model Engineer In Thailand

Some of the things I need for my hobby are readily available in Bangkok. But finding them is another matter.

The other model engineer I mentioned is planning to come to Pakchong (Pak Chong) from the Bangkok area to buy some of the materials I have mentioned are available here.

What you need as a model engineer in Thailand may be available somewhere, but Thailand is such a massive country and Bangkok in particular is a huge city and very difficult to get around that the main problem is finding out where to get what you want.

Resources

One of the main purposes of this website, therefore, is to build up lists of suppliers and resources. There is now a Resources section on the website with 14 pages of resources ranging from suppliers names and contact details to lists of resources on other websites.

Join The Announcement List

So if you are a Model Engineer or just interested in home workshop, DIY, metalworking or anything mechanical in Thailand or South east Asia, please join the announcement list and become an active member of the model engineering in Thailand community. We need you and your knowledge.

Other Pages In This Section

Join The Announcement List

Join the Announcement List and I’ll let you know when new content is posted on the website.

I’ll send you a brief email summarising what is new and you can decide if you want to visit the website to get more details or not.

Simple!

Click Here to go to the Form to Join the Announcement List.

Please Leave Your CommentsBelow

Please leave your comments and/or questions below. Comments will not appear until I have reviewed it. (Too many comment-spam-bots) Your email address will not be shown. Thank you. Alan

Hi there all you modellers,

I am into scale model aircraft and mainly these days 00 model railways, especially Hornby. I am completely amazed that despite the maufacturing centre of Hornby being just across the way in China, there is absolutely nothing in Thailand for the enthusiast.

I am living in Udon Thani, which is six hours drive from Bangkok. For those in Udon, there is one model shop near the Udon Pit School dealing in ARTF kits, helicopters, and speed boats. Has a decent range of materials, but principally for the ARTF enthusiast.

Scratch built, and detailed scale builders looking for choice woods of various sizes and covering materials for example will find it lacking, and fuel? I have seen one other shop in the town dealing in mainly radio controlled cars.

Robinsons in Central Plaza used to have a large range of plastic kits, glues, varnishes, paints, air brushes, and general building tools. Note the word ‘used’ because Robinsons in their infinite wisdom have removed all of this in its entirety from their store! All i could get from their staff was that the company had ‘taken it back.’

Anyone else have any further details of well stocked model engineering outlets around Udon Thani, or must we go to BKK or import from the UK to get any decent building materials around Udon Thani?

Good question! Hornby? You either import it in or go without!! I have seen nothing in Thailand. Can anyone enlighten me as to an outlet anywhere in Thailand?

Hi, such a pleasant surprise this morning to find this site.

I am a brit retired here for some time now. Ex UK Merchant Navy. I am interested in live steam mainly.

Funds permitting in the near future I shall be upgrading my lathe and milling machine.

Presently using a Unimat 3, good for what I need at present but limited size wise. A Proxxon excuse for a milling machine, again limited but small cuts and a lot of fiddling and I can generally achieve what I want.

Looking forward to future exchanges

Pete

Hello Peter and thank you for posting your comment about you machine tools.

Nothing wrong with small machines and small models so long as your eyesight is good!

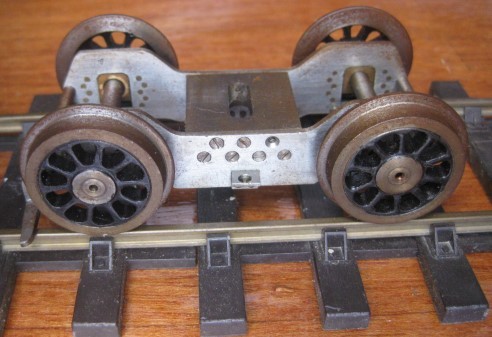

Look at my Gauge 1 Black 5 bogie for example, it’s tiny.

http://modelengineeringinthailand.com/models-alans/gauge-1-black-five-bogie/

Welcome to the engineering modelling community in Thailand and

Chok Dee

Alan

I have been looking into a decent priced mini lathe and ran across your site. I have also found http://www.smartcncs.com/?lang=en which have quite a few models of lathes and hadn’t seen them mentioned here. Prices are quite high in my eyes but I figured I should at least let you all know of them.

Hi Duke and thanks for your comment.

I have seen the smartcncs website before but looking at it again today they have improved their range of machines including ones from Germany and Taiwan. They are showing many machines I have never seen before.

I don’t know of anyone who has made a purchase from this company though.

This is a superb looking lathe:-

http://www.smartcncs.com/product-en-718509-5820009-LD+1216GH+TAIWAN+Gear+Head+Bench+Lathe+406+mm,+Special+Price,+Free+Delivery,+2+Year+warranty.html

And look at this milling machine:-

http://www.smartcncs.com/product-en-1101042-6556256-%E0%B9%80%E0%B8%84%E0%B8%A3%E0%B8%B7%E0%B9%88%E0%B8%AD%E0%B8%87%E0%B8%81%E0%B8%B1%E0%B8%94%E0%B8%A1%E0%B8%B4%E0%B8%A5%E0%B8%A5%E0%B8%B4%E0%B9%88%E0%B8%87%E0%B8%82%E0%B8%99%E0%B8%B2%E0%B8%94%E0%B9%80%E0%B8%A5%E0%B9%87%E0%B8%81%E0%B8%A3%E0%B8%B8%E0%B9%88%E0%B8%99+BF20Vario+%E0%B8%88%E0%B8%B2%E0%B8%81+Optimum+Germany+%E0%B8%84%E0%B8%B8%E0%B8%93%E0%B8%A0%E0%B8%B2%E0%B8%9E%E0%B8%94%E0%B8%B5+%E0%B8%A3%E0%B8%B2%E0%B8%84%E0%B8%B2%E0%B8%9E%E0%B8%B4%E0%B9%80%E0%B8%A8%E0%B8%A9.html

If within budget I’d suggest that German made followed by Taiwan are better quality than Chinese.

It’s a very handy website and since I’m looking for a replacement motor and/or controller for my Sieg C4 I’ll see if they can provide one.

You say the prices are high but it depends what you are comparing with. If you import from say USA or UK you’ll have shipping charges, Thai VAT and customs duty to pay. From my experience this can almost double the original purchase price.

Plus. And this is VERY important. If you buy in Thailand and have problems with it or need spare parts or upgrades you can always go back to the shop.

Much more difficult if you imported your machine.

One last point. If at all possible go to the shop rather than buying online. Not only can you see what you are getting but you will build a relationship with the supplier and that could be very important in future.

Once again thanks for sharing your information with us.

Alan

I noticed that many of the lathes sold by smartcnc use the D1-4 spindle, but when I emailed them with the hope that they would also carry, or could at least order, various chucks with the D1-4 mating connector, I was disappointed by the return email stating that do not carry D1-4 chucks.

Does anyone know of a good lathe chuck supplier here in Thailand?? I recently purchased a 6″ 3-Jaw with a plain back and I’m having a local machine shop custom make a D1-4 backplate; I’ve also ordered the three cam-studs from a supplier in the USA. I’m still looking to purchase a 6″ 4-jaw and I’ld love to buy one with a D1-4 back side.

Hi Mike,

Thanks for your enquiry.

Did you find your D1-4 chuck and/or backplate?

I bought a D1-6 faceplate and a backplate for my big Kinwa lathe from Forcelink, the company who supplied it.

Unfortunately they no longer have a website. This is their address:-

120/39, Soi Kingkaew 21/2, Bangplee, Samurprakarn, Bangkok 10540,

Here is the Google map and satnav coordinates:-

https://goo.gl/maps/VrMdP

13 40.243140000000004

100 deg 42.94409999999971

You can try sending an email to the person I deal with, Joe who speaks excellent English.

weixia35 AT truemail.co.th

I’ll also circulate your enquiry to the Announcement list subscribers.

Hope this helps.

Alan

Alan, thanks for the link to the machine shop supplies dealer, I will drop by with my new plain-back 4-jaw chuck and see if they can sell me a D1-4 backplate for it. The same machine shop that made my lathe spindle also made a D1-4 backplate for my 3-jaw scroll chuck, but I gave the shop the 3 cam studs (which I had bought from a US supplier via the internet) , so they didn’t need to make them. It will make my life much easier if the shop you bought from can also help me.

BTW, I no longer live in Nong Khae,…my wife & I moved down to Bang Saen a few months ago and we both love it down here.

Best Regards,

Mike

Hi Alan,

I have been looking at that 1224 as well. I think that may be the one I end up with, it is a nice looking machine.

I intend to ship a 20 ft container from the US as well. There is a provision in Thai customs about returning Thai citizens and household goods. We will put everything in my wife’s name. She has been outside of Thailand since 2004, so easy to prove her as a returning expat. I even have a Harley Davidson that is in her name. Rule used to be that a vehicle that has been in a Thai persons name for more than two years can be imported duty free.

It will be interesting for sure.

We will be making a trip next month to see friends and family and do some house hunting.

Later,

Matt

Hi Matt and thanks for the update.

It’s a long way off before you buy your lathe in Thailand and by then I guess the LD-1224GH TAIWAN Gear Head Bench Lathe 610 will have been superceded by then.

Just a few observations based on my experience with my Sieg C4 Lathe:-

The topslide is lousy! I had to make quite a few mods to get it to work and it’s still too sloppy to give a good finish. The Gib strip is on the wrong side. It looks like it’s on the right side on the 1224.

The C4 (like the 1224) doesn’t have a leadscrew handwheel. When cutting up to a shoulder at least the last few mm (if using power feed) have to be cut using the saddle traverse handwheel which is very coarse. Min is graduated in 0.5 mm which is no where near fine enough.

The above issue could be circumvented if there was an automatic feed trip and a dead-stop carriage stop. but there isn’t.

Fitting a leadscrew handwheel is a top priority on my C4.

Another very annoying niggle that I MUST put right is that the saddle traverse handwheel has to be pushed in to engage the drive. (In hand feed mode). It can all to easily – and it does – drop out of engagement and then the feed-dial setting is lost. Crazy!

Some of the above points will probably apply to any similar lathe so watch out fro them please. And don’t buy blind! Go to see the machine before you buy.

About the returning Thai Expat rule I think you are on the right tracks with this. I couldn’t do that because Kanyah had been living in Thailand for around 3+ years before we imported the container.

Good luck with the house hunting!

Best Regards

Alan Brown

Gents,

I am very pleased to have discovered your website today. I have lived in Thailand for about a total of 7 years on a couple occasions. I am married to a Thai lady and we are planning to make our final relocation there in early 2016. I work in the middle east at the moment and need to continue until the finances support our move. Anyway, I love the small home machine shop stuff and plan to make a very nice shop there.

If you are looking for tools and material, there is a supplier called Ruam Charoen (sp?) in Ban Chang that is excellent. I spent a couple years as a Field Engineer working on Royal Thai Navy ships at the Chuksamet port in Sattahip. I went to RC at least 3 times a week to get materials for fixing the ships machinery, including the 1200 psi steam systems. They were great, if they didn’t have what I needed, they could always find it and have it the following day. Ban Chang is a little bit of a drive from where you are, but would make a nice day trip. Some good restaurants at the beach and a little bar area in Ban Chang that is quite unique.

When I was in China I learned about the mini machines that were available and saw that most of them were made by a company called Seig in Shanghai. Since I was there I arranged a visit to the factory. I bought a small mill and lathe and made an extra bedroom in the apartment into a mini machine shop. I had to sell everything when I left as the shipping costs were just too high and I didn’t really know where I was going.

Sieg’s website lists “http://www.smartcncs.com/?lang=en” as their distributor in Thailand. I was wondering if anyone has used them yet?

When we make the final move to Thailand I will be shipping quite a lot of tools from the US but buying machines there. It will be good to tap into some experience for some advice when that day comes.

Best regards,

Matt

Hi Matt and many thanks for your contribution to the website.

I looked up Ban Chang on Google maps and see that it’s in Rayong not so far from Pattaya. There is another Model Engineer down in Pattaya, George, and that area of Rayong according to Glen is the centre of industry in Thailand. So plenty of reasons to visit.

Looking at Ban Chang on Google images also shows the place has many delights apart from model engineering!

Not sure how I would find the Ruam Charoen shop, though.

I took a look at the website of the Sieg Mini-Lathe dealer in Thailand that you mentioned – http://www.smartcncs.com/?lang=en – and they do display many mini-lathes and mini-mills. Most seem CNC type and they also display CNC accessories such as stepper motors, stepper-motor drives and XY tables for example.

The shop is located tot he North of Bangkok at Pathum Thani. Their address and a map are on the website.

Also I noticed some larger geared head bench lathes like this one for example: “LD-1224GH TAIWAN Gear Head Bench Lathe 610 mm”. That’s a really neat machine and beats my own Sieg SC4 Lathe my a long shot.

So many thanks for the tip, Matt, I will certainly be adding this website to the Resources Section of the website under the Suppliers Of Tools For The Model Engineer In Thailand Section.

By the way I imported my Sieg SC4 Lathe along with my complete model engineer’s workshop from the UK. It came along with household effects in a 20 foot container.

You used to be able to avoid paying import duty by coming to Thailand on a Retirement Visa but hat has stopped now. It’s probably cheaper buying your mini-lathe here in Thailand as you intend to do rather than importing then from USA.

Please feel free to ask for any advice as and when. If I can’t answer there are many people on the Announcement List whom I can call on for advice.

Once again Matt thank you for your contribution and welcome to the group.

Alan

I found the following address info for Ruam Charoen using Google:

83/50 Moo1, Pla, Banchang, Rayong 21130,Rayong,Thailand

Here’s the web link with a map:

http://tha.soopage.com/company/RUAM_CHAROEN_GROUP_CO_LTD_4Ce.html

Please note that I have not visited this location to verify it’s correctness. Perhaps Matt or George could help verify this location is correct?

Hello Alan,

I’m all too happy to share photos and descriptions of my diy CNC mill,…it’s not too often I get to present a show-n-tell to folks that actually know what an R8 quill is. I sent you a brief description with some attached photos to your modelengineering…@gmail.com.

If you don’t get them or you want me send somewhere else, just let me know. I see no way to upload or attach photos via the “comment” section I’m using to write this reply.

Because I’ve chosen to use an different working fluid than water for my steam engine, much of the design concerning “sizing” will be a lot of guess work for me. The expansion properties of water to steam are well known and documented, meaning a designer pretty much knows how many feet of 1/2″ tubing he needs to produce a given quantity of steam at known temps and pressures.

I’ve yet to find similar tables or formulas for the fluid I’ve chosen to use. I will use either a standard axial flow or a Ljungstrom design for the turbine itself, both have their pros and cons, but I favour the Ljungstrom (designed in the late 1800s and used on at lease one steam locomotive).

Somewhere in a box I’ve yet to unpack are my very rough sketches of some of the parts such as the forced air burner/boiler, and as soon as I find them, I’ll scan them into a pdf or jpg file and send it off to you,…I’d love to get your feedback.

Send me an email when you want to meet up,…Pan (my wife) & I are always eager to make new friends.

Best regards

Mike Murray

Hi Mike and thank you for your very interesting comment.

I have copied your comment and added mine in the text below.

I’m all too happy to share photos and descriptions of my diy CNC mill,… it’s not too often I get to present a show-n-tell to folks that actually know what an R8 quill is.

I sent you a brief discription with some attached photos to your email address. If you dont get them or you want me send somewhere else, just let me know. I see no way to upload or attach photos via the “comment” section I’m using to write this reply.

(Alan’s comments)

Mike, I have the description and write-up thank you. I’ll upload them as soon as I get a minute.

I must look into providing the facilities to allow uploading photos into comments.

(/comments)

Because I’ve chosen to use an differant working fluid than water for my steam engine, much of the design concerning “sizing” will be a lot of guess work for me.

The expansion properties of water to steam are well known and documented, meaning a designer pretty much knows how many feet of 1/2? tubing he needs to produce a given quantity of steam at known temps and pressures.

I’ve yet to find simular tables or formulas for the fluid I’ve chosen to use.

(Alan’s comments)

Calculation of flow of liquids and gases in pipes is a common engineering procedure – the equations are well known and there are many software solutions available. I regularly calculate pressure losses in pipes mainly for water, compressed air and natural gas.

Complex fluids ie mixtures of liquids/vapours/gases are much more complex to solve.

Now I use a software program called Pipeflow Wizard which is available from http://www.pipeflow.co.uk/. There is a free download to play with.

Whether it’s suitable or not for your probably depends on the kinnd of fluid you are using. If it’s a vapour/gas mix then probably not.

(/comments)

I will use either a standard axial flow or a Ljungstrom design for the turbine itself, both have their pros and cons, but I favour the Ljungstrom (designed in the late 1800s and used on at lease one steam locomotive).

(Alan’s comments)

Showing my ignorance this is the first time I have heard of the Ljungstrom turbine, but I am familiar with the Tesla turbine which would be easier to construct.

(/comments)

Somewhere in a box I’ve yet to unpack are my very rough sketchs of some of the parts such as the forced air burner/boiler, and as soon as I find them, I’ll scan them into a pdf or jpg file and send it off to you,… I’d love to get your feedback.

(Alan’s comments)

Many thanks, Mike, love to get this section of the website up and running.

(/comments)

Best Regards

Alan Brown

Greetings all. I’ve been following Alan’s retirement saga for a bit over a year now,…very happy that he added this seperate machineshop site.

I’m a recently retired (January this year) electronics engineer who has always enjoyed playing in a machine shop. I’m not a dedicated model engineer but some of my toys may well be considered models as they are somtimes simply scaled down versions of existing devices; over the last few years I built a smallish CNC milling machine, which I’m still fine tuning and learning how to use.

I moved to Thailand from the U.S.A this past February, and I’m temporarily living between Saraburi and Nong Khae, which is near my wife’s family.

I brought many of my hand tools with me,…my CNC mill, rotory table, electric drills, multiple tool boxs, DMM, etc.

Like several here, I too have a keen interrest in “steam” power, but with a bit of a twist,… I dont want to use water as the working fluid,…I prefer using an organic working fluid,…which means my engines must be closed cycle.

I will also be using a turbine instead of pistons. I want to build at least two seperate systems,…one will use solar heat to boil the working fluid, while the other will use a more traditional forced air oil burner. Both systems will spin an electric generator to produce electricity.

Of course, most of my plans are on hold right now while my wife and I look for our perfect retirement location.

I’m very much looking forward to learning where and who, all the best suppliers are,…like Alan, one of my first builds, or purchases will be a nice heavy duty workbench….any suggestions?

Mike M.

Hello Mike and many thanks for your comment.

I should firstly mention that I am presently in the UK packing my (UK) workshop and household belongings to send back to Thailand. It’s a massive task. I have ordered a dedicate 20 ft container and we (myself and my wife Kanyah) are busy packing.

The separate ModelEngineeringInThailand.com website I thought would bring more focus to the model engineering (machinist or workshop hobbyist) people in Thailand and indeed in the short time it has been running I have made many friends learnt a lot about where to get tools and materials we need for our model engineering hobby in Thailand – as indeed have many other people. From what you have written, Mike, you sound exactly like the kind of person this website is being built for.

You sound very competent to have built a CNC milling machine. Any photos of it you could let me have to post on the website? Many people would be interested to see the machine.

Your closed cycle engines sound very interesting. Are you designing them yourself? If you have any more information or sketches I’d love to put them on this website.

I see you are near Saraburi which is only an hours drive or less from our house in Pakchong. Maybe when we are back in Thailand we can meet up sometime?

Good luck with finding the ideal retirement location. Pakchong is picturesque and quiet but the place is booming – up-market houses being built everywhere and land prices rocketing. The cost of land has risen three or fourfold in as many years.

For materials and tool suppliers please see the Resources Section of the website. There is a lot more information to be added when I get the time.

As to a workbench as you know I made a steel one. It looks rough but does the job. I also have some nice folding tables with a white plastic surface – easy to keep clean.

Best Regards

Alan Brown

Yes, finding a supplier of Fuller’s ale has really made life in Thailand almost perfect!

Fantastic stuff on the TR3A.

By the way, I think everyone should watch some videos of this guy, to put a smile on your face;

https://www.youtube.com/watch?v=J3766FEkaqQ&list=PLGjbAdaOBLBkaiyL8nzQTXzLnkmeFfpz-

He must be the grandson of Heath Robinson. Good to see eccentric home engineering is live and well.

Hi Ian and thanks for the info. Great stuff.

Can’t think why I would need a faster toilet but if you have any ideas on how to build a half size steam traction engine (Savages’ Little Samson) fast I would be interested.

Not only do I now have London Pride, I received a box of London porter yesterday! Courtesy of Shaun of Cromwell Tools.

Best Regards

Alan Brown

Hello Alan and Everybody,

Fantastic what you guys are doing, good luck with the projects.

I have lived in Thailand 30 years, 14 years in the north. My interest is classic Brit motorbikes (so far just Triumphs and BSAs); restoring, building, maintaining and riding them, for myself and friends.

I have a small workshop at my home in Chiang Rai. I found this website through Shaun at Cromwell Tools. Shaun has been most helpful over the last couple of years. I got a beautiful UK made spiral fluted reamer with pilot through him (specifically for line boring swinging arm bushes) and I also bought a mini lathe and mini milling machine from him together with many hand tools. I also buy old British made tools on ebay, often through this seller, 1412jas;

http://www.ebay.com/sch/1412jas/m.html?_nkw=&_armrs=1&_ipg=&_from=

Just seems right having your own King Dick in your hand sometimes…. double ring end spanner of course.

I don’t know anything about large machines I’m afraid.

I recently found both a waterjet cutting shop in Chiang Mai, where I had a wheel embellisher made in aluminium 5083, for my Triumph Morgo cafe racer. He has a great variety of metal stock, in various forms. Stainless, bronze, aluminium, also nylon; flat, round, hex, hollow etc. I am going there in a week or so to get some hollow bronze to make some bushes. I have photos of his stock but can’t see how to post them here. There is also a laserjet cutting shop in Chiang Mai.

Best wishes

Ian

Hi Ian and thanks for the comment.

Great to hear from you and to make a new acquaintance in the field of home workshop.

Shaun of Cromwell Tools mentioned you when he was here yesterday delivering my order for cutting fluid and a crate of Fullers London Porter! (English beer) Great guy Shaun and their Cromwell Tools catalogue is amazing. I recommend everyone to get a copy.

As to the BIG Lathe and Mill, it’s not all about big machines. I have a tiny Emco Compact 5 Lathe and mill back in the UK which is smaller than your mini lathe and it’s just the ticket for small components.

If you have some photos to put on the website please email them to me and I’ll upload them.

I thought people could add photos when they post a comment but apparently not. I’ll look into adding that facility.

I once ‘rebuilt’ a Triumph TR3A sports car. ‘Rebuilt’ means i replaced a lot of rusty body panels with fibreglass ones (shame) but the pride of the restoration was the engine. I put a whole room aside for that project in the house, installed a lathe ans completely re-built and tuned up the engine. I had it up to 105 mph when the engine was run-in and boy that was scary! Slow by modern standards but not bad for a 1960’s car.

Anyway thanks again for posting and please send the photos and name of the shops if you have them.

Best Regards

Alan Brown

Ronnie Lim Consultants are the Pacific Rim Representatives of York Portable Machine Tools, Canada.

York design and manufacture portable in-line boring machines and bore-welding machines for the convenient and speedy in-situ repairs of heavy equipment and certain applications in the Oil and Gas industries, and general engineering.

Let me know if you have any applications that York Portable Machine Tools Canada can offer you. Being in the same time zone in South East Asia makes real time communication that much more convenient, and I hope we can collaborate to mutual benefit.

Regards

Sincerely,

Ronnie Lim

Ronnie Lim Consultants

Pacific Rim Representative

York Portable Machine Tools, Canada

134 Edgedale Plains #07-70

Singapore 820134

Tel: +65-6241 2148 Mobile: +65-9671 9156

Hello Ronnie and thank you for the information about the supply of portable in-line boring machines.

I personally don’t have any immediate need for your portable in-line boring machines but I am posting your comment because someone else visiting the website may be interested there are many types of people who visit ModelEngineeringInThailand.com

Best Regards

Alan Brown

Hello mike

Thanks for the kind words and the order today see you before month end mate

we know have the new 2014 catalogue available so if anybody would like a copy please send me your address and I will post you one

hello Alan I will be up to see you next week if that’s ok a few issues down here but all ok at Cromwell

my mobile is 081 803 2653

Shaun

Hi Alan, yes Shaun is one of the good guys. 8″ shaper only about 300kgs. 20′ Containers i bought outright in the UK in 2003 for £1500 each, but they were top of the range insulated ones. And then i kitted them out as workshops.

May be worth inquiring with some BKK shippers to quote you in bringing your workshop over here. Shipping a container door to door should not be more than $2000. You can rent or buy, in 2003 the cheapest container bought outright with a 2 year shipping certificate was £500 + vat.

Hope this helps,

Mike.

ps, i also have a Thai friend who imports machine tools direct from China, no middleman, recently he imported a very high quality new Bridgeport clone for 150k baht, cheaper than the UK prices or anything in BKK.

Hi Mike,

Thanks again for that very useful information.

I’ll look into the container idea to bring the workshop over. The machines I have there are on the small size but ideal for making the smaller parts. even a big traction engine has small parts.

A Bridgeport clone would be ideal for building the traction engine – it’s a favourite for that purpose.

I had a quote for a similar sized milling machine (and a large lathe) from All Arm Co when I went down to BKK to pick up the tools and cutter grinder. I’ll check that price out and put it on the website.

Once again thank you for the advice.

Best Regards

Alan Brown

Hi Alan,

more into making stuff for the workshop and my motorcycles than models, but on top of being a “petrolhead” am also a “machinetoolhead”. I’m from the UK too, moved here 10 years ago in Udon Thani in the NE near the Laos border. In 2005 i brought over in 2 containers my household and workshop goods inc lathe etc, Snap On tool boxes and motorcycles. without declaring the bikes, the customs duty was a reasonable 70k baht. My machine shop here comprises a 1969 VSL Boxford lathe, fully tooled, 1973 Tom Senior mill with the quill feed Vertical head, 1979 8″ Boxford shaper, a Stent T&CG and all the usual stuff like bench grinder, linisher, pillar drill etc.

Regarding tooling, Cromwells have a big warehouse in BKK, the manager is a nice chap from England called Shaun Burke. May be worth talking to him.

Regards,

Mike Hayward.

Hi Mike and thanks for the comment. It’s great to hear from fellow machinists here in Thailand even if they aren’t primarily involved in making models.

You have a very impressive set of workshop equipment. that 8″ shaper must weigh a ton or more. I like shapers – wish I had one.

I’m very impressed by your transportation project. 2 containers must have cost a fortune. I’ll probably sell my UK machine tools and just bring the bits and pieces over. It seems to me that importing stuff from UK is just too expensive.

Andrew put me touch with Cromwell Tools and I got a phone call and an email from Shaun Burke. He is coming up to Pak Chong to see me in the new year.

Please keep in touch and contribute as appropriate to the website content.

Best Regards

Alan Brown

Alan,

My workshop is already in Bangkok, I am renting a small shophouse in Bangkolem area, but we moved house so I will have to drag it across town – but not too far.

I first set up my workshop in Bangkok in 2004, and since then have packed it up, moved it to Taiwan for 3 years, packed it again and moved to Dubai for 4 years, packed it again and came back to Bangkok. Hopefully this will be the final move! I ended up paying about THB 9,000 in customs duties fir the whole workshop equipment. The company I used was Boonmah and they are good and have the proper lifting equipment for lathes, milling machines, etc.

We have a 5-story townhouse and the ideal place for the workshop would be the utility room on the 5th floor! But I think that would be asking too much of the workers to lug everything up there!!

The casting yard is for concrete works (I am in civil engineering) so it was used for expressway segments and rail sleeper segments, tunnel segments, etc. Plenty of space but not so scenic for spending the weekends there.

I believe the Rob Roy is a 3.5″ gauge ax I was thinking about making that one myself, but ended up making a Simplex by Martin Evans. Now started work on a BR MK-1 coach with Commonwealth bogies (about 1.8m long).

Regards

Andrew

Hi Andrew and thanks for the commentary.

Interesting you moving your model engineering workshop all round the world.

If you built the Simplex loco in it you must have some pretty decent equipment.

My workshop in the UK is in an upstairs bedroom. I have a 4″ lathe and a decent size milling machine, pillar drill and badsaw as well as two benches and another smaller late etc in there!

Some photos on the Workshop Page of RetiringInThailand.net website.

It was a real (and dangerous) struggle to get the machines upstairs and installed on the cabinet stands. I winched them up the stairs using a steel-rope winch and lifted them in place with a car-engine crane. Even so I had to take the head off the milling machine and take it up in two parts.

Best Regards

Alan Brown

Hi Alan & George,

Its a good idea to get a data base of suppliers in Thailand that are suited to model engineering. Although I can get quite a few tools from China Town area it is the steel sections that are difficult to get. There are many shops selling large steel sections but they are too large, sell only in 6m lengths and the composition of the steel is questionable/not known.

I’d like to know if you have found a supplier of silver steel in round bar form.

Also, has anyone built a 5-inch gauge track yet in their garden. I have a steam locomotive but no track as yet, but my company have ‘promised’ to let me use part of their casting yard to build one. Lets see what happens there.

Regards,

Andrew

Andrew, very many thanks for your comment and welcome to the Model Engineering in Thailand fraternity. There are now three of us! (That I know of.)

Supplier’s Database

For the database I have plans to make it a proper database that individuals and companies can enter details directly i.e. doesn’t need my intervention. It will be searchable and have groups. e.g. steel, brass, hand tools, machine tools etc.

It’s not a difficult thing to set up using WordPress – I just have to get round to doing it.

I have heard about China Town but when on a visit to Bangkok, more precise directions would be appreciated. I can imaging spending hours walking round there looking for stuff.

I will be inputting Sat Nav coordinates to locate suppliers premises when I input to the database.

Steel Sections

As to steel sections, have you seen the Ying Jaleaum page? Plenty of steel sections (no small BMS (Bright Mild Steel) sections though) and there and there is no minimum length – they will cut what you want.

But you are right about the quality of the Thai steel. It’s dead rough, hard to machine and difficult to get a good finish particularly compared to the free-cutting Mild Steel we are used to in the U.K.

Other Materials (See La Borigaan)

See La Borigaan (in Pakchong) have a stack of stainless steel and other non ferrous materials like brass, bronze and cast iron. I have loads of movies and photos to put on the website.

Silver Steel I have not found but you can buy Key Steel – the Thais use it for making keys to hold flywheels and pulleys on the shafts. I haven’t tried it but I’m guessing that it high carbon steel therefore hardenable. I will buy a piece and test it.

5 Inch Gauge Locomotive Track

I don’t know of any model railway track in Thailand. George in Pattayah has a part built rob roy which I think is 5″ gauge so he would possibly be interested in a track.

Casting Yard

When you say casting yard are you referring to as in a foundry? Could we get small castings made there?

Moving A Model Engineer’s Workshop to Thailand

Andrew, in an email you mentioned moving a workshop to Thailand. I would be very interested in that project since at some stage I will have to do it. I’m thinking to move it next year around June/July. In my case I will maybe sell the big lathe and milling machine because of the huge transport costs if I have bought new ones here.

You do know that the Thai customs will charge you a fortune to get your stuff released? Perhaps your company will be paying for the shipping so in that case it’s not such a big deal.

Hi Andrew,

I had a visit from Shaun of Cromwell Tools this week. He personally delivered my order for soluble cutting oil, Sherwood STD tapping fluid and a case of Fullers London Porter! Amazing personal service.

The tapping fluid and London Porter I have tried and can thoroughly recommend. The soluble oil trial will wait until I get my big machine tools properly commissioned.

As to round silver steel (and this is the reason to responding to your question) Shaun says that Cromwell in Bangkok now stock it.

Best Regards

Alan Brown

Just wanted to be the first

Hi George, you are the first to comment here and welcome.

Alan Brown

modelengineeringinthailand.com