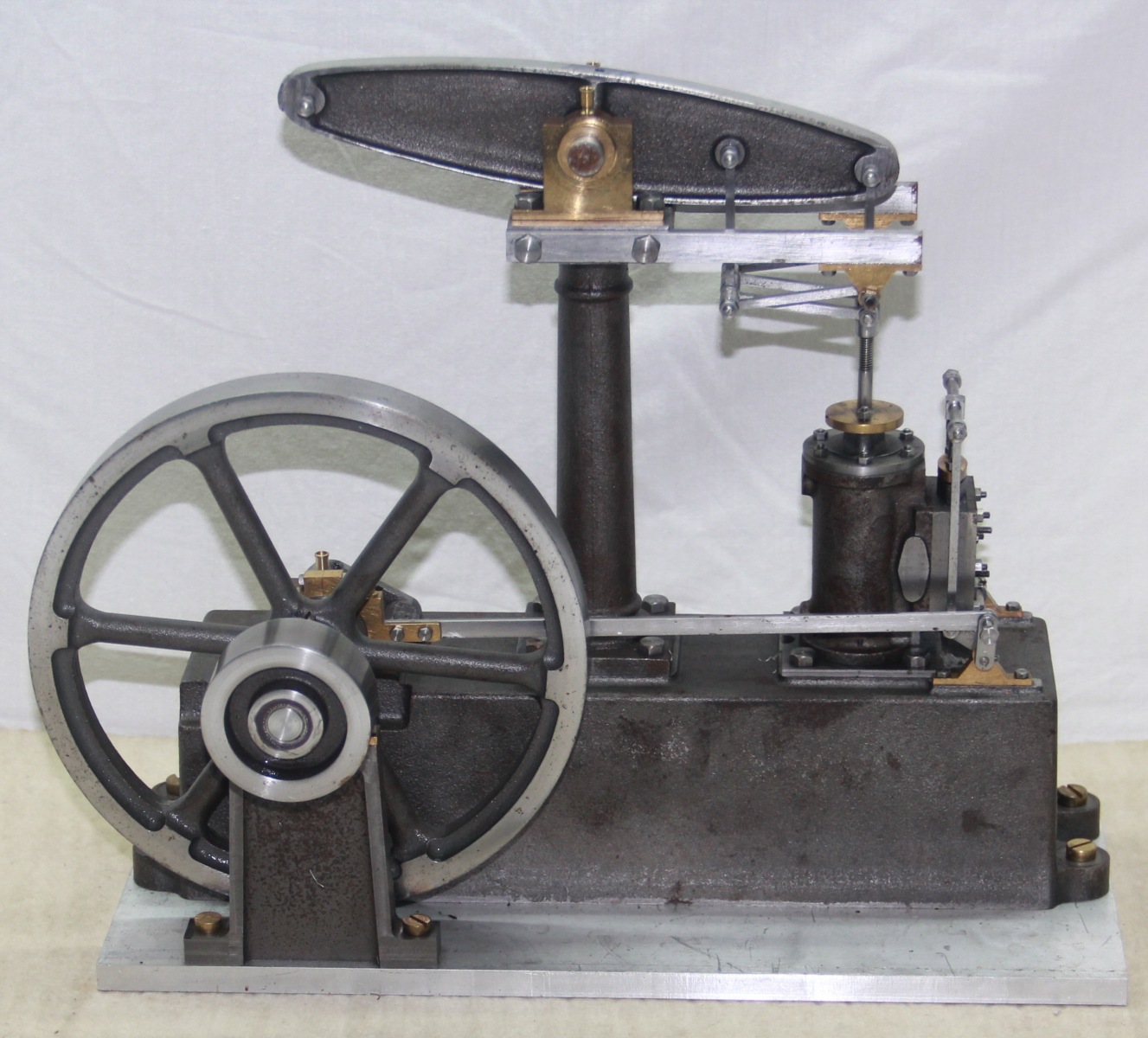

Photos Of George’s Stuart Turner Model Beam Engine Nearing Completion In Pattaya, Thailand

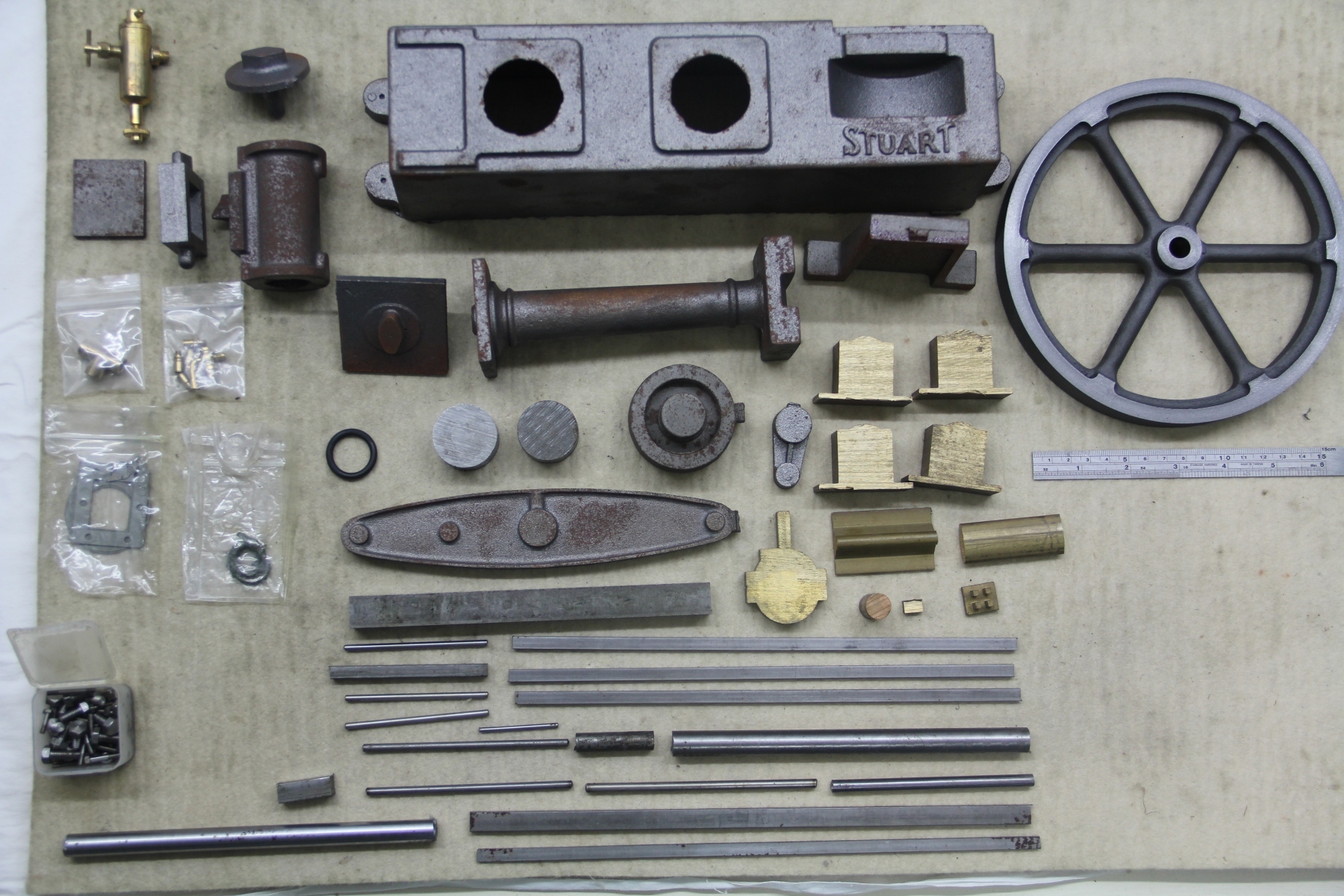

Not much of a narrative with these photos, they tell the tale by themselves, particularly as George has gradually removed all the pieces from the Stage as they were transformed into finished parts. A nice touch George that adds much interest to your photos.

Here is the email from George – who lives in Pattaya – enclosing the beam engine photos:-

| Good morning AlanThanks for the latest photographs of the Stuart Turner Victoria mill Engine connecting rod.Looks like it is coming along fine.I have, I hope, included a few shots of the Stuart Turner beam engine.

To get the curved filet on the good end I used a round piece of tool steel held in a tool holder made by eccentric engineering from Australia. I find if I am using HSS tools on the lathe these holders are very easy to use and work very well regrinding is a breeze with the small jig you get with them. I am going to order a right hand one when I get back to work in six days time. After getting this far I could not resist trying to get the engine running well you just can’t can you? So I fitted the connecting rod set up the timing and turned on the air increased the pressure to ten PSI and away she went A very happy man displayed his achievement to a very bewildered wife who’s only comment was “So what does it do”? Oh well!! I see you have added a few extra pages to the web site. The photos of the bogie show a high level of workmanship. As do all of the other projects. Puts my bodged conn rod to shame. I hope all is well with your ongoing projects. As I said before the web site gets better each time I log on keep up the good work. Regards George |

The first group of photos are displayed in slide show format.

George has gradually removed all the pieces from the Stage as they were transformed into finished parts.

Next, I have trimmed some of the photos to show you close up’s of some of the components of the Beam Engine.

So that’s it for George’s Stuart Turner Beam Engine Photos on this page but please check out these additional pages:-

Other Pages In This Section

Please add your comments below.

+1. I use the EE tangential too, mostly for roughing. I have just made a fantastic new finishing tool from 5/8″ HSS

called a vertical shear tool. Google Gadgetbuilder who describes the tool and angles. It is also in the moltrecht books under shaper tooling where the idea comes from. Very easy to make (only 2 angles), and makes the most fantastic finish on steel or anything. Who needs cylindrical grinders? It is THAT good. Max DOC about 0.003″ but with this tool, half a thou is easy. Swarf is incredible.

Mike

Mike,

Thanks fir that website reference -eventually got round to looking at it!

I may try that tool first before indulging in the EE tool. Maybe save the EE for my Christmas prezzie!

I often have problems getting a good finishing cut, so hopefully this will be a welcome addition to the tool box.

Regards,

Andrew

George,

Good work on the beam engine and glad that everything works fine. I think us model engineers will always be misunderstood by our other halves as they wonder why we continue to make these “toys”! I keep explaining that model engineering is a health benefit and will keep our minds and bodies active well into old age. I’m not sure if that was the answer she was seeking haha!

I have seen the eccentric engineering tools you mentioned and have often thought of investing in one. So as you have had some good results I will probably indulge myself. I tend to use HSS tooling quite a bit fit good finishes and detailed turning. I use the insert tools for roughing out.

Regards,

Andrew

Hi Andrew and thanks for your comment.

If I can add my experience of the tangential turning tools.

I don’t get a good finish from them. I have tried rounding the corner but to no avail.

Conversely they are good at turning into a sharp corner.

My experience of the CROBALT tools sold by Eccentric Engineering;-

The tangential type are as good or better than carbide inserts for roughing and unlike the inserts you can sharpen them. I have some amazing videos of them in use – I’ll dig one out and post it on the website.

Also I have the

Eccentric Engineering CROBALT FoR Parting-off tool and it works a treat.

The tangential tools often drop in the holder especially on a dig-in. Most annoying.

I used one ground for screwcutting to cut some 5/8″ whitworth threads on the Kinwa 430×1100 lathe.

I had two issues here although I did screw-cut all 24 bars in the end:-

I couldnt work out how to use the jig provided to grind the 55 deg angle so I did it free-hand – not ideal.

Being tangential and with a 55 deg included angle viewed meant that the tool was very fragile and it kept breaking.

Another drawback with the tangential toolholders is that there is a lot of overhang leading to tool spring. This isn’t so noticeable when the tool is in a toolpost on the cross-slide but It was a serious drawback when trying to machine the taper on the Stuart Turner Victoria Steam Engine connecting rod with the tool in the topslide. Just too much total overhang so I had to grind up two (right and left hand) traditional tools from 3/8″ HSS.

Don’t let the above put you off though but don’t expect them to be panacea.

By the way George used round section tools to get a neat generous radius on his StuartTurner Beam Engine and I have yet to tray round tools.

Hope the above will be useful.

Best Regards

Alan Brown