Mikes CNC Slant Bed Lathe Part 03 – Frame, Table, Linear Ways

Tubular Steel Frame

The frame was completely built at local welding shop in Rayong, Thailand.

Photos Taken by the Welding Shop 16 Sep 2015

The next photo shows how the threaded steel block & nut are welded to frame for bed adjustment screws.

Only the wall of the steel tube is threaded for bolting the bed in place against the frame,…I wanted a thread inserts but couldn’t get them.

Linear Ways

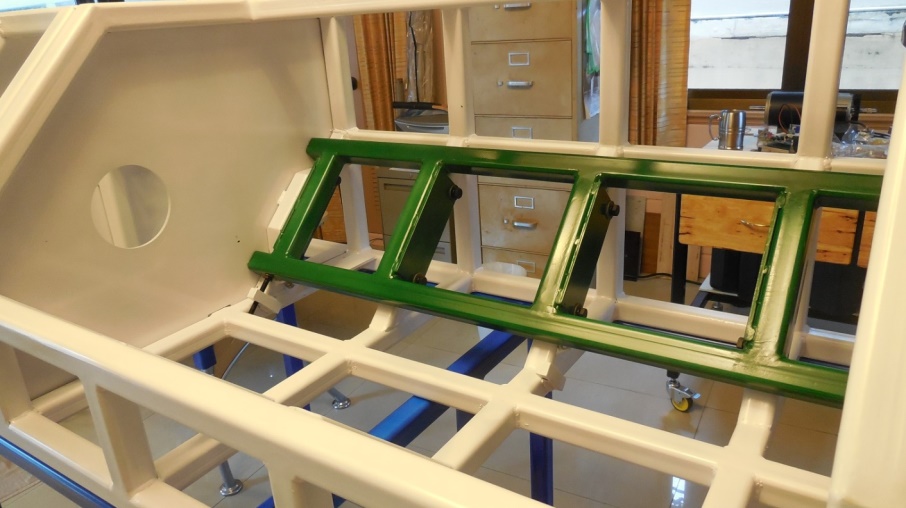

Photo below shows the green bed assembly bolted into white frame. Notice plates vs tabs bolted to frame. This is an early photo taken before the Lexan strips were epoxied onto the surface and holes were drilled into the bed to mount the two Z rails.

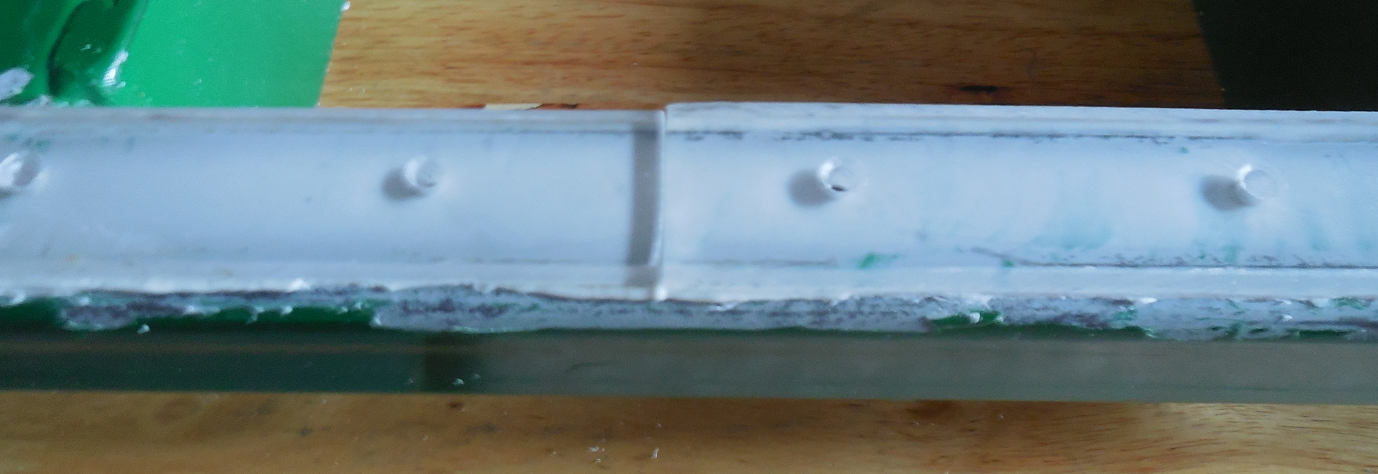

And here ae the Lexan strips 1.1” wide x 6mm thick were epoxy glued to the top surface of the steel tube lathe bed “ladder”. Used Bosny Epoxy putty, sold as a Concrete filler epoxy & purchased at Home Pro, to fill in gaps between steel tubes & Lexan strips, and glue them to the steel. The shiny Lexan surface allowed me to view reflected images which showed ripples, indicating it needed to be machined flat; and it was.

Clear Plastic Windows

Found a plastic shop in Chon Buri, Thailand, located several blocks north of Central Plaza Mall.

Top: 115cm x 21cm x 3mm — 170Bht ~ $4.78

Back: 115cm x 15.5cm x 3mm — 150Bht ~ $4.22

Lid/Door: plastics shop cut, bent & mounted 3mm thick Acrylic sheet in place.

850Bht ~ $24.00

Table

Lathe frame is not fastened to table shown below, but is held in place horizontally by the 4 angle iron tabs welded into each corner. Only the lathe’s weight holds the lathe down.

4 hanging 6” long tubes & the front two legs will be used to attach two drawer slides for future drawers.

X & Z Carriages & Rails

Ordered from China (linearmotionbearings2008) & shipped (mailed) directly to Thailand:

o Great customer support from: Chai cgxfred@aliyun.com

o CAUTION: Most of the Bearing Blocks were shipped missing up to 10 ball bearings.

o Box of 100 steel ball bearings, 0.125” diameter for the PDF bearing blocks; they fit perfectly. Ordered from US company.

-8 linear bearing blocks: DFH15B $116

-2 rails, each 1100mm long: DFH15 $72

-2 rails, each 358mm long: DFH15 $24

-1 Anti Backlask Lead screw Ballscrew SFU1605 &

-Ballscrew L1000mm overall length+ end machining+1set Bearing blocks BK/BF12 $47

-1 Anti Backlask Lead screw Ballscrew SFU1605 &

-Ballscrew L310mm overall length+ end machining+1set Bearing blocks BK/BF12 $40

Shipping and handling $65

Total $364 USD

358mm rails are too short; Ordered 500mm DFH15 rails to replace them. Total: $62.00

Rail Bed Aluminium (1100 alloy) plate 6mm x 115cm x 43.2cm

4cm X 4cm X 143cm aluminium extruded tube; used for Z axis alignment.

Future Pages

We’ve now covered 4 out of 16 topics!

Next section will be about the X &Y drives.

Please Leave Your CommentsBelow

Please leave your comments and/or questions below. Comments will not appear until I have reviewed it. (Too many comment-spam-bots) Your email address will not be shown. Thank you. AlanOther Pages In This Section