Construction Of The Half Sized Little Samson Traction Engine Has Commenced In Earnest As Machining Starts

Today, 14 September 2014 marks the day I started constructing the 6 inch Little Samson Traction Engine Model as I start work machining the hub castings for the front wheels.

And I must say how exciting it is and how ‘natural’ it feels machining these big pieces of metal.

As will know if you have kept up to speed with me on this website I prefer machining or simply working on big components rather than the small to tiny ones in most model engineers models – my other models included.

Maybe this comes from my early days after I left school at 16 and went to work as an apprentice in the machine shop of agricultural machine manufacturers Bamfords Ltd of Uttoxeter, Staffordshire, UK.

There I was machining full sized crankshafts, flywheels, pulleys and so on for petrol and diesel engines. I was working on machine tools many times the size of even my large Argo Mill and Kinwa lathe.

But I digress. And just to digress a little further before I show you the Little Samson Hubs being machined let me update you on the de-rusting process and let you into a secret to successfully de-rusting.

How To Remove Rust From Cast Iron And Steel Without Mechanical Cleaning – Secret Revealed

I have been showing photos on this website of how I remove rust from the Little Samson traction engine castings using Thai Cleaning Vinegar.

I have had mixed results with this – sometimes the castings end up being more rusty than when I put them in the vinegar bath!

The Secret To Removing Rust With Thai Cleaning Vinegar (Or Citric Acid) Lies In The Timing

The secret is to pull the casting (or other steel part) from the vinegar bath at the right time. This is when most of the rust has been dissolved but there are still traces left. If you leave it in the bath any longer it will start to rust all over again – and very severely!

A few hours soaking is all that is needed – not overnight and certainly not days.

Look at the photos of the Little Samson traction engine back wheel hub castings in the photos below.

Before the vinegar bath it was severely corroded, Beyond surface rust it had developed large areas of a thick rust crust that was thick enough to measure and could only be removed mechanically by chipping at it with a cold chisel!

I pulled it from the pickle after a soak of about six hours. I didn’t time it but it was all done in daylight on the same day.

After a quick scrubbing with a stainless steel pan scourer and a hose down with cold water it was as clean and as bright as new.

The problem was (and this is an issue with all forms of chemical cleaning) that being chemically clean and wet it soon started to develop a new film of rust,

[flagallery gid=25]

You can probably make out a slight brown colour to the castings in the photos above. that is a rust bloom even though they have been out of the vinegar bath for only a couple of minutes. I have sprayed them with a rust-preventive penetrating oil in an attempt to halt the new corrosion.

Enough of this little digression into de-rusting cast iron – now let’s look at machining cast iron bar for the front wheel hubs of the Little Samson traction engine.

Obtaining Large Sized Cast Iron Bar In Thailand

The starting place for this little story was this email I sent to the owner of Little Samson Models, from whom I bought the castings and drawings:-

| Hi Edward.

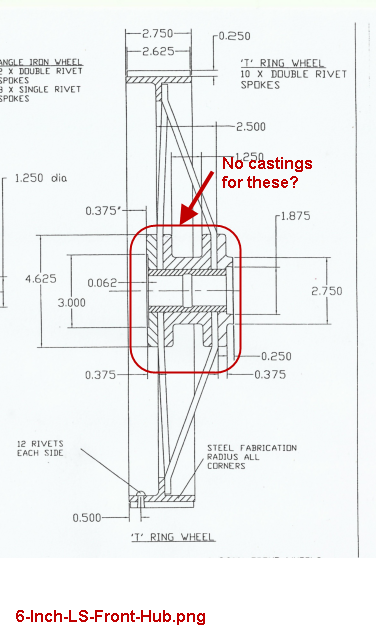

I’m getting geared up to actually start making some parts for the 6″ Little Samson. I have made a couple of front trial wheel spokes and milled a grove in a large piece of cast iron as a trial ‘hub’ to see how the spokes will fit. So when I moved on to actually machine the front hub I found I didn’t have a casting for them. Thinking I may have lost them somewhere I looked through the list of castings I bought and can’t find them listed. Nor can I find any castings for the front hub cover plates and the front hub wheel bearing. Attached image shows the parts I am referring to. If there are no castings available for these I’m pretty confident I can find some cast iron or appropriate size in Thailand but I just wanted to check with you first. I would prefer UK castings as Thai cast iron is very coarse grained. Sorry to be a pain to ask such a stupid question. Attached: 6-Inch-LS-Front-Hub. Kind Regards Alan |

This is the drawing I attached to the email:-

| Hi Alan,

I do not do castings as most builders prefer to use steel, cheaper! A bit of steel bar would do the trick, suggest aim for free cutting and get them to saw slices for the cover plates as well. Hope all is good with you. best wishes, Edward |

Well, I could foresee some heavy machining with mild steel and doubted if I could find free cutting type here in Pakchong. Not in these small quantities especially.

But I did know where to get round cast iron sections and that was at the Teera Borigaan shop.

Sure enough they had the right sizes in stock, took my order and I collected the lumps of cast iron the next day. (By the way at the visit to buy the cast iron I also placed the order for the front and back wheel rims and welded-on flanges – but that’s a story for another day.)

So let’s look at the round cast iron sections I bought for the front wheel hubs.

Here are a couple of photos:-

[flagallery gid=26]

Notice that little traction engine wheel? That’s a front wheel for the 3/4″ Burrell traction engine model I started making in UK. It’s shown sitting on the hub of the 6″ scale Little Samson front hub material!

Machining The Cast Iron Bar To Make The Hubs

The photos below tell the story pictorially. Here is the sequence in words:-

Machine the rough cast iron bar on the lathe to a nice cylinder.

Turn the central grove.

Machine the fillets in the corners at the bottom of the grove. (Had to make a fillet form tool first. The tool and the throw-away insert were both home-made)

Turn the hub covers. (Not shown in the photos)

Mount the hub on a rotary table and drill the hub-cover-securing holes through hub cover and hub together.

Machine the spoke groves using a 20 mm dia three-tipped carbide insert end mill.

Turn over the hub and machine the spoke groves in the other side making sure they are in the correct agular position.

Put back the hub cover and countersink the holes for the securing screws.

Remove the hub cover and tap the holes in the hub for the securing screws.

Assemble the hub and the two cover plates with socket head countersink screws.

Repeat for the other wheel. Easy!

Here are the photos:-

[flagallery gid=28]

Leave a Reply

You must be logged in to post a comment.