This Is One Batch Of Tools I Am Importing To My Model Engineering Workshop In Thailand From My U.K. Workshop

The tools were sent to me by my son, Alex, by U.K. Royal Mail (Parcel Force) and as of writing this the parcel has arrived at EMSEVT LAKSI MAIL CENTRE in Bangkok at 0503 this morning.

This is the list of tools I asked Alex to send me. I made this list from memory since I know where I keep everything and what I am missing most in my model engineers workshop here in Pakchong (Pak Chong), Thailand.

Please note this batch is in addition to the tools I already have and another batch of tools I ordered directly from RDG tools in the U.K.

| 1. Tap& Die Set Metric NormalWhere: Office. “Plastic drawers”” on floor near bookcase.

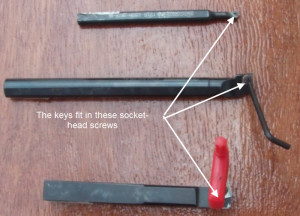

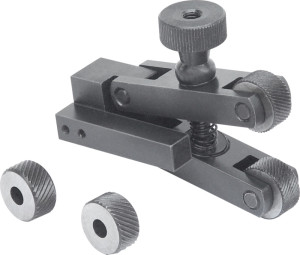

These will be one size in each drawer. Each draw should have one drill, one die and two taps. They will be marked something like M10, M11 etc.One or two of the draws will have a white Label saying something like M10, M11.The range will be from about M3 to M12. 2. Headband Magnifier Where: Workshop. “Over Lathe” 3. Small Carbide Insert Tool (Key) Where: Workshop. On bench “Cutting Tool Place” Need key for the tiny boring bar. Below, more details of the carbide insert tool. If in doubt send all of them. 4. Knurling Tool Where: Where: Workshop. On bench “Cutting Tool Place” This is home made. A commercially made one looks something like this:- If there are any spare wheels (called knurls) please send those too. 5. Taper Test Bar Where: Workshop. “Cabinet 1 Over” Left hand side. 6. 3 MT Rotating Centre Where: Workshop. “Cabinet 1 Over” Right hand side. In wooden box. 7. 2×2 Gear Cutters (Total 4) Where: Workshop. “Cabinet 1 Over” Right hand side. 8. Small Drilling Vice Where: Workshop. “Cabinet 1 Over” Right hand side (Might be in the workshop near the little lathe) 9. Reamers Where: Workshop. “Plastic Drawers on Bench” In several Drawers. 10. Optical Centre Punch Where: Workshop. “Cabinet 2 Over”. In plastic tube. Where: Workshop. “Cabinet 2 Over”. In plastic tube. 11. Centre Finder Where: Workshop. “Cabinet on Floor”. In wooden box. 12. Wiggler & Centre Finder Set Where: Workshop. “Cabinet on Floor”. In plastic wallet. 13. 61-80 Drills Where: Workshop. Shelves 1. in plastic box. 14. DRILLS SET 1MM – 6MM ( IN .1MM STEPS ) Where: Workshop. Shelves 1. 15. DRILLS SET A-Z Where: Workshop. Shelves 1. 16. Endmills Where: Plastic Drawers (2) on Bench. Bottom two rows. 17. Dial Test Indicator And Holders Where: Cabinet 2 Over. Bottom shelf. Below is the holder for the Dial Test Indicator. 18. ER40 COLLET CHUCK AND FULL 28PC COLLET SET (3-30mm) Where: Could be on the floor near Wooden Cabinet and/or on the top of Cabinet 1 Over. Comprises three components. Two aluminum ‘suitcases’ and one (or two?) chucks. (Chuck(s) not in any box) Above, the aluminum suitcases. I bought another chuck separately. Here is a photo of it:-

|

Your “centre finder” is actually called a “co-axial indicator” or “co-ax indicator” for short. Very handy tool. I have just ordered one from the States for $68, (about £42) shipped free to a friend’s adress in San Fran. He’s bringing it over on his next visit in April for me in his suitcase.

The optical centre punch; wanted one for ages, retail anywhere between £37 to £50, easy to make, the only difficult bit is machining a suitable piece of perspex/acrylic rod and getting the domed convex end right, then polishing out any machining marks. Found some perspex rod, machined the convex end using my ball end turning fixture (home-made), machined the holder off centre from some brass, machined a centre point punch and ground the centre point on my Stent T&CG, jobs a good ‘un. Cost – zero, but about 10-12 hours work. Works very very well.

Love making my own tools.

Regards,

Mike.

Hi Mike and thanks for the comment,

That ‘centre finder’ or ‘co-axial indicator’ is great. I use it on the milling machine to centre the rotary table which may have for example a piece of work in a three jaw chuck that has been machined on the lath and now need indexed milling. Typical item would be the slots in traction engine hubs to take the spokes. It only takes a couple of minutes to locate the exact centre under the mill spindle.

I have thought about using it in the lathe eg when trying to line up a centre mark on a piece of work held in the four jaw chuck. I haven’t tried this yet so I don’t know how successful it would be.

You made your own optical centre finder! Well done. The box on mine says Made in USA. Perhaps that’s why it was so expensive. They don’t seem to make these in China.

On the subject of making tools I avoid it at all costs. If it is available I will buy it. After all I am a model engineer and any time spent in the workshop not making models is lost time to me.

Actually that’s not quite true now. I do make jigs and fixtures that aid the model making, either to improve accuracy or to speed up production when more than one piece has to be made.

And I do understand that making tools can be very rewarding. They can form a little mini project where you have something useful made complete in a short space of time whereas making a model is a long process and you don’t see the end result for months or years. If I have to make a tool I’ll do it and be satisfied when it’s made. I have spent weeks making various backplates for chucks and collets chucks to fit the lathe and the rotary table for example.

Thanks again for the comment.

Alan