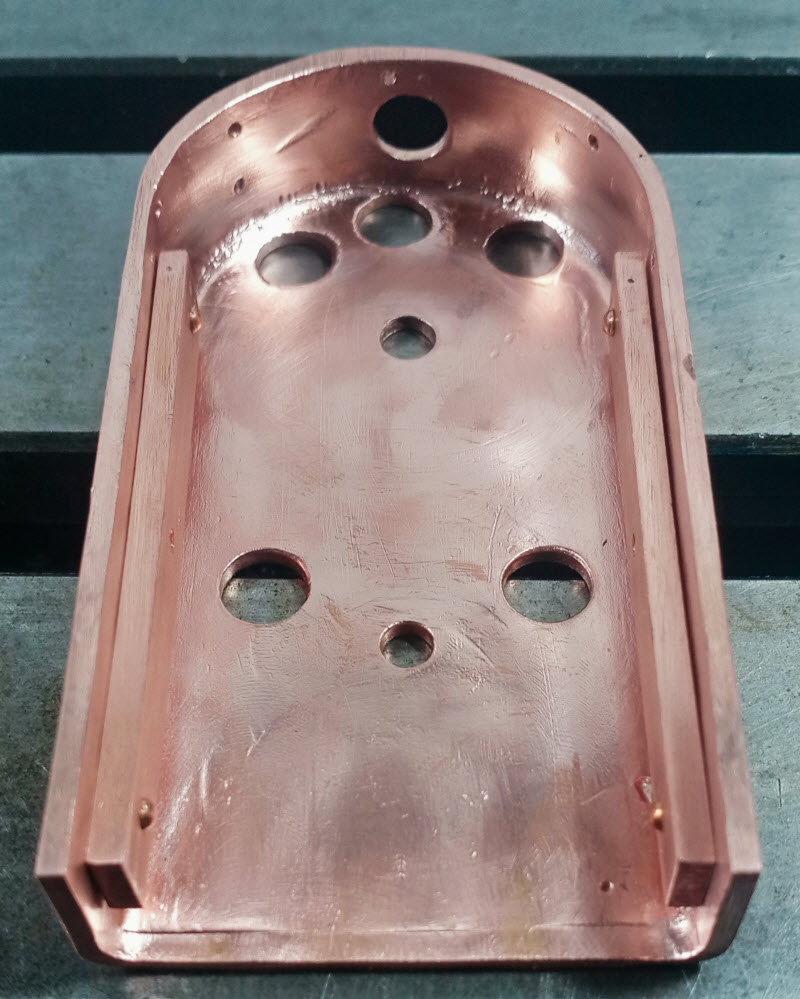

Test Assembly of All The Copper Boiler Parts

The boiler is assembled as if for silver soldering to check fit, alignment etc.

Superglue is used liberally to hold the parts while they are drilled 1/16″ and 1/16″ diameter rivets pushed into place the rivets were not superglues because they would all have to out again as the boiler is dismantled.

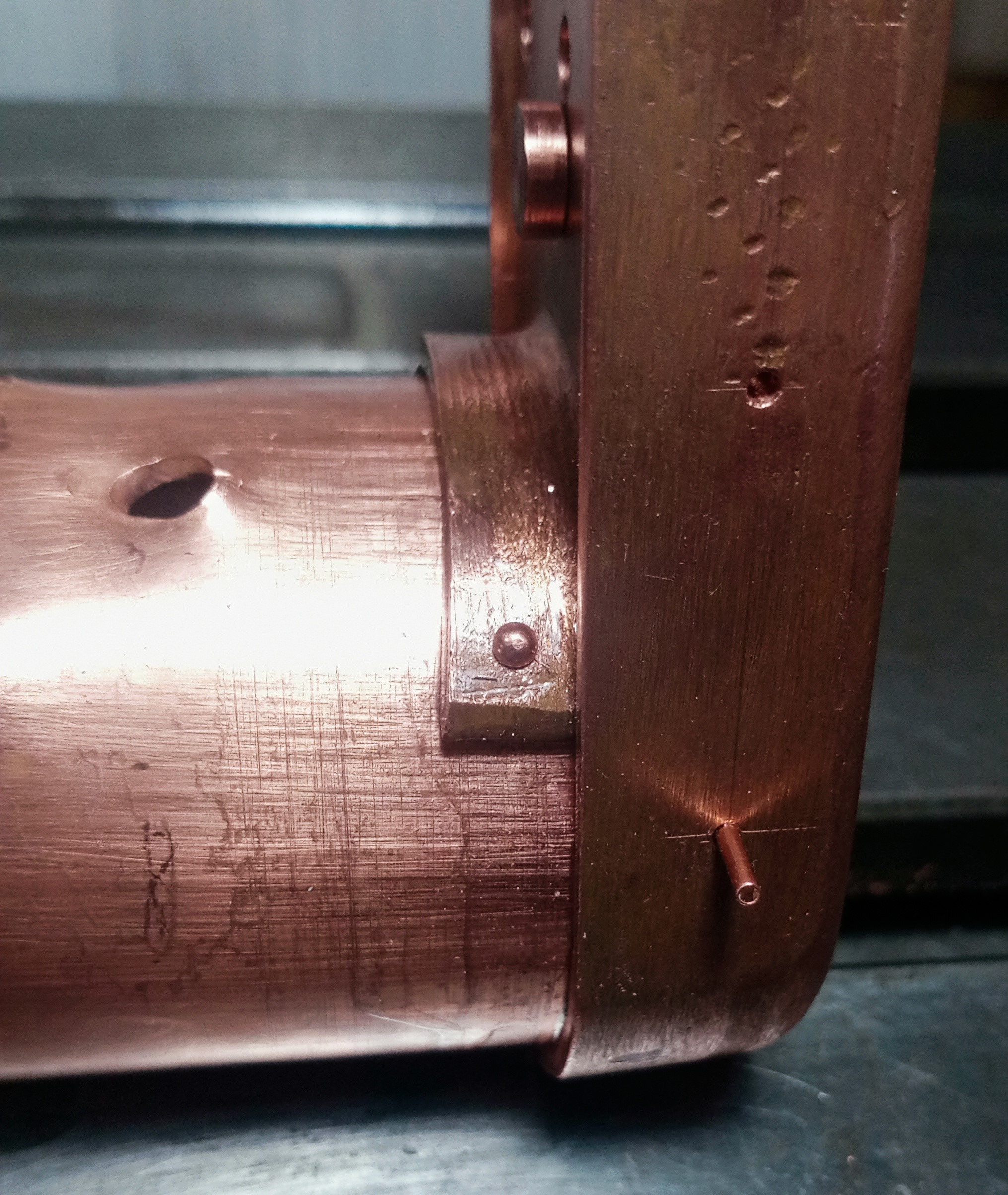

A start was made by securing the copper strips that will support the Throatplate and end of the boiler and also close the gaps that were reported on the questions page.

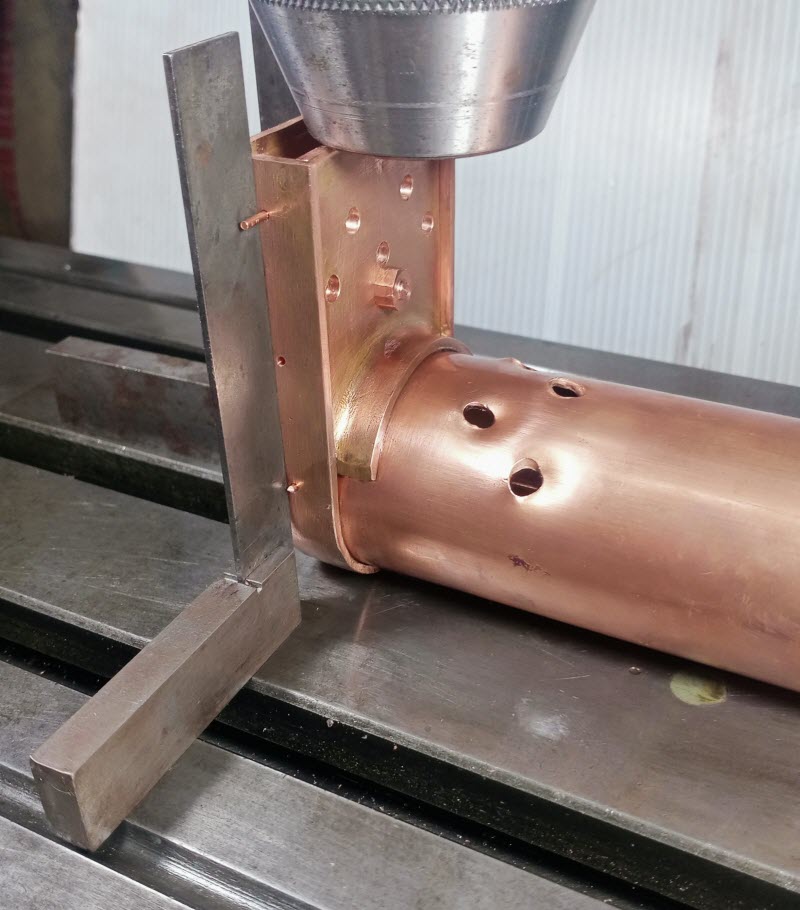

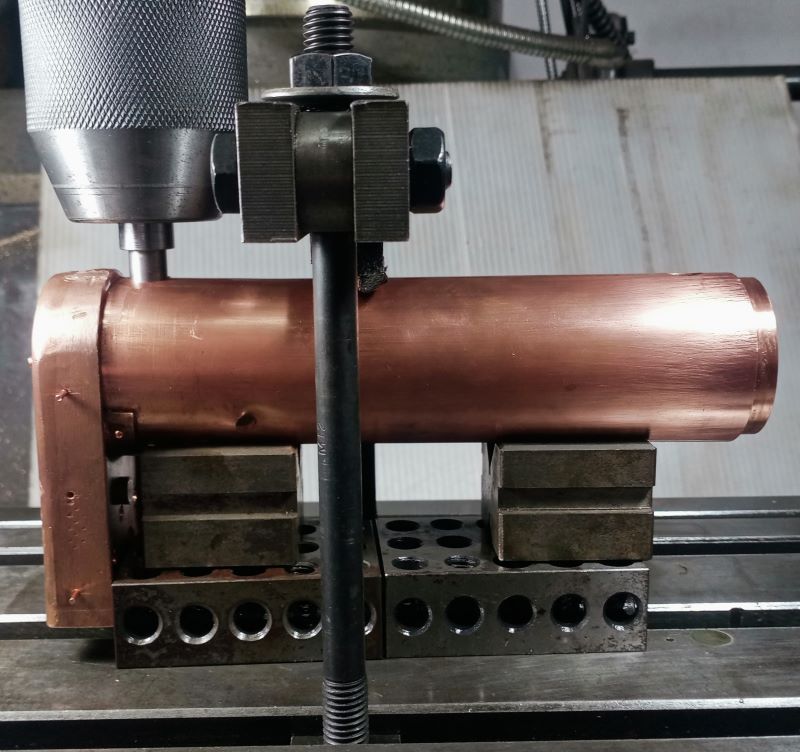

Next, the Throatplate and boiler was added and carefully squared up. The mill drill chuck was used to push the parts into close contact.

Using feeler gauges, the gap between the Throatplate and boiler was determined to be between .002″ and .004″ – ideal for silver soldering:-

And so the assembly continued, always checking squareness and adding rivets.

A plug turned to fit the Safety Valve bush opening was used to align the boiler square with the sides of the Backplate.