Flanging The Remaining Boiler Plates – A Brutal Process

I mentioned in the first page on flanging copper boiler plates that – contrary to what the ‘experts’ taught – I found that flanging almost 1/8″ thick boiler plates is a brutal task demanding a heavy hammer and heavy blows with it. All will be revealed herein.

On this page I’ll be dealing only with the Backplate. The Throatplate will be on another page

The Wooden Formers

Whilst the flanging former for the Frontplate was a simple steel round disk, the formers for the Backplates would need to be more complicated in form. As recommended by the ‘experts’ I therefore chose to make them from wood. If they worked fine – if not then over to steel or aluminium.

Just to summarise what the experts say about formers:-

Expert and Book Author No 1

“For all thicknesses up to 5/32” (this is over 1/8″ – my copper is under 1/8″) hard wood is a perfectly satisfactory material…

…to make metal formers is a waste of time and money.”

(I have added the note in italics)

Expert and Book Author No 2

“The use of solid steel former plats is essential…”

Making The Wooden Backhead Former

This photo shows how I made the first former from heavy duty plywood:-

Forming The Copper Backhead Plate

This photo shows the first stage in forming the Backhead plate. Wooden former in the vice and lightweight plastic hammer.

You can see immediately that the wooden backer is unable to keep the copper plate flat.

To help resolve this I added two wooden support disks as shown below:-

This setup worked for just one more round of annealing and forming with the results as shown in the Gallery below.

You can see what a hideous mess these coper boiler plates are turning into. Added to that the wooden disks split up.

I blamed two things:-

- Lightweight hammer

- Wooden (as opposed to solid metal) formers

I was wondering if I had just produced an expensive pile of scrap copper.

So I set to and made steel formers. (Which I should have done in the first place)

Making And Using Steel Formers And The Big Hammer

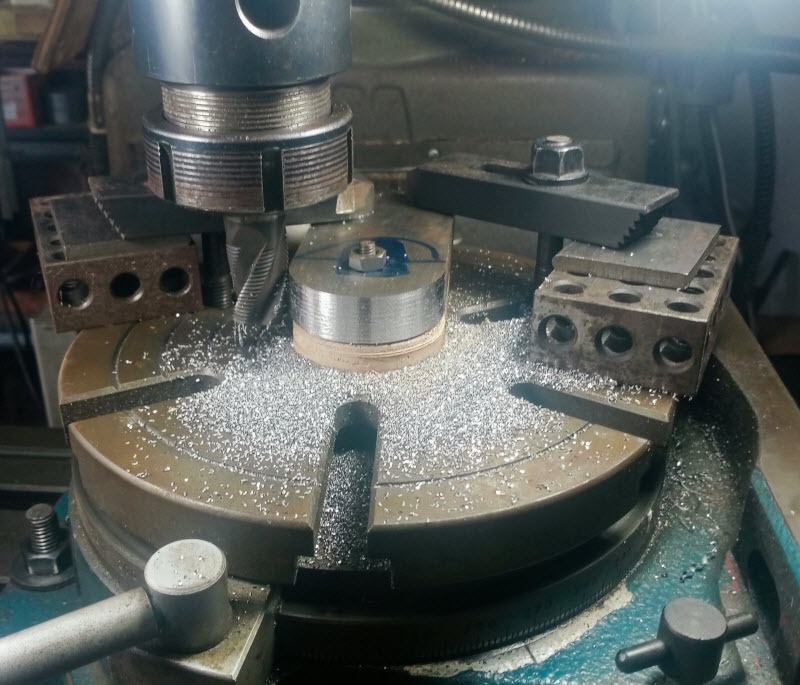

This Gallery shows how I made the steel former for the Backhead:-

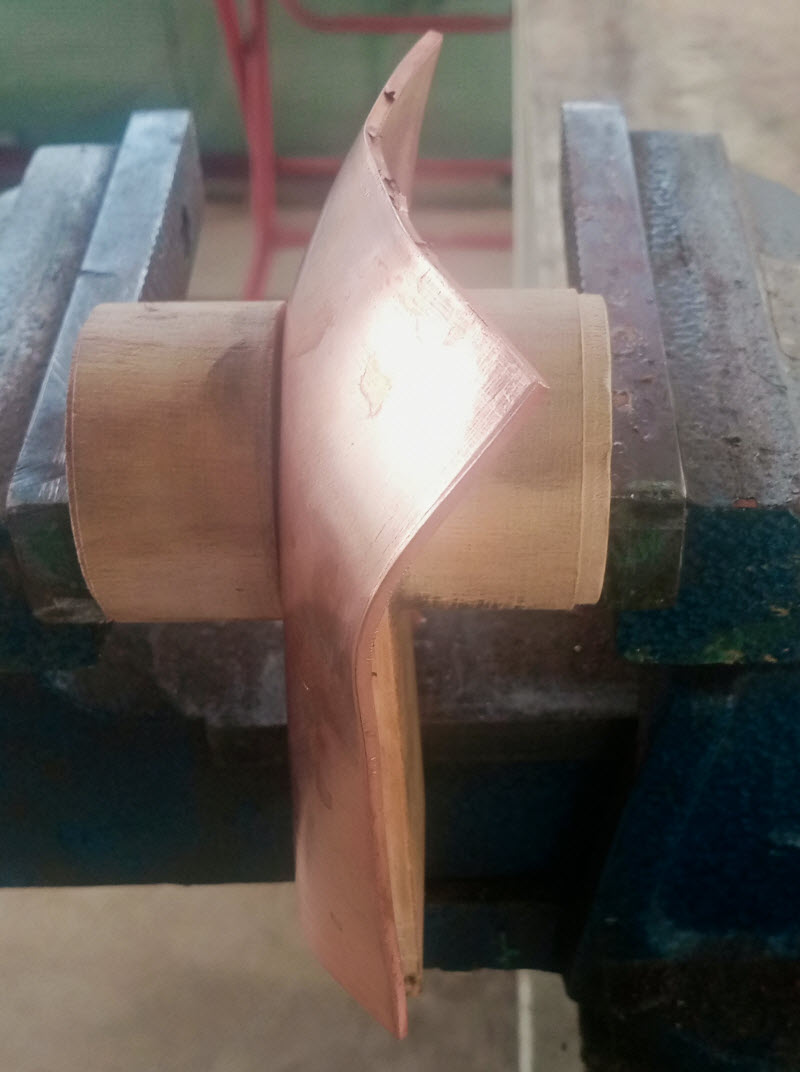

And this Gallery shows how easy it became to neatly flange those messed-up pieces of scrap copper into useful boiler flanges.