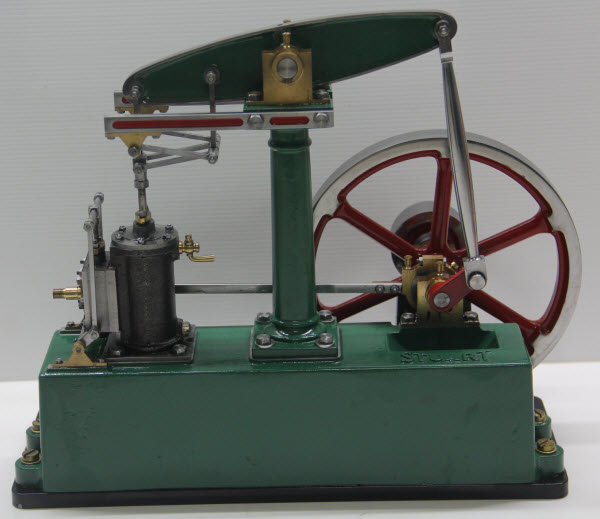

George’s Stuart Turner Beam Engine Is Now Operational And Looks Splendid In These Photos

These updated photos of George’s Stuart Turner model beam engine that he has built in Pattaya, Thailand, show the engine complete and operational a and painted.

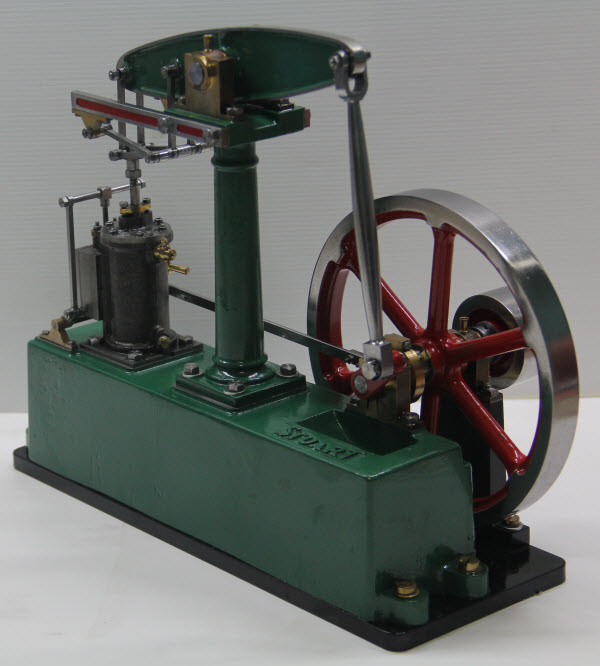

Here is another view of the same model steam engine:-

It’s certainly a fine looking model and the steelwork and cast iron bright parts are really gleaming. The ‘fish-bellied’ connecting rod has come out really splendid.

George has reported that the engine as shown above has been run on compressed air but not steam yet.

This is what George said when he sent me the photos:-

| Not very happy with the result and I will blast the paint off the base and re-machine the part where the central column attaches to the main base. The parallel motion still has to be polished and the cylinder requires final machining. |

Please add your comments below.

Hi all,

I have the same boiler kit that George has, and like George I keep putting off building it. Not because I don’t have a big enough heating torch but because I’m scared of wrecking it with too much heat/not enough heat and silver soldering all the parts in the wrong place.

Also I want to finish the Victoria steam mill engine before I make the boiler.

Properly planned it shouldn’t actually be difficult but building the half sized Little Samson traction engine and finishing off Victoria is enough for me at the moment.

Hi Mike, George is in a better position to answer rather than myself.

I would suspect that the engine will run on very low pressure, say 15 to 20 psi.

As to a boiler I don’t know if George has any plans for that but I do know that he is weighing up his next project which is a twin cylinder horizontal mill engine, not a steam boiler.

On the subject of the quality of George’s Stuart Turner Beam Engine model I agree with you totally. The craftsmanship is something to aspire to. The fine finish on the cast iron parts (e.g. flywheel) is outstanding in my humble opinion.

The beam engine looks fabulous to me; very detailed craftsmanship. What steam pressure will it run on? I look forward to seeing pics of the boiler/burner assembly.

Good morning Mike and fellow metal benders.

Thanks for the comments.

At the moment I still have to do some work on the cylinder and the parallel motion, mostly cosmetic.

It turns over smoothly at about 10 PSI. I do have the parts to make the vertical boiler sold by the now defunct GLR they also supplied the castings for the mill engine (Tina) Which I am also building. I need to buy a large cyclone heating torch before I start work on the boiler. Making the boiler for my Rob Roy was an eye opening experience.