Full Details Of The DIY CNC Milling Machine Designed And Constructed By Mike

Mike kindly sent me these photos and some description of the fully functional DIY CNC milling machine that he designed and constructed himself.

Mike didn’t actually determine to build a CNC milling machine straight-off. His goal was to build one (or more) steam turbines and he appreciated that a CNC mill would be necessary to machine the curved blades.

Mike looked at the cost of having these specialist part manufactured by hi tech tool shops in Silicone Valley where he was living at the time and the quoted prices were all more than Mike was ready to pay.

So, since building the steam turbines was to be a fun hobby project Mike thought he would deign and build his own CNC milling machine also as a fun hobby project.

The result of this idea is what you see on this web page.

Each photo of the home made CNC milling machine shows a certain aspect of it’s design and construction.

I’m not an expert on CNC milling machines so can’t really add much commentary myself. I would say though the the short article “How I Built My CNC Milling Machine” my Mike is a very informative and readable document and is available for free download as explained below.

So on to the photos of the CNC milling machine:-

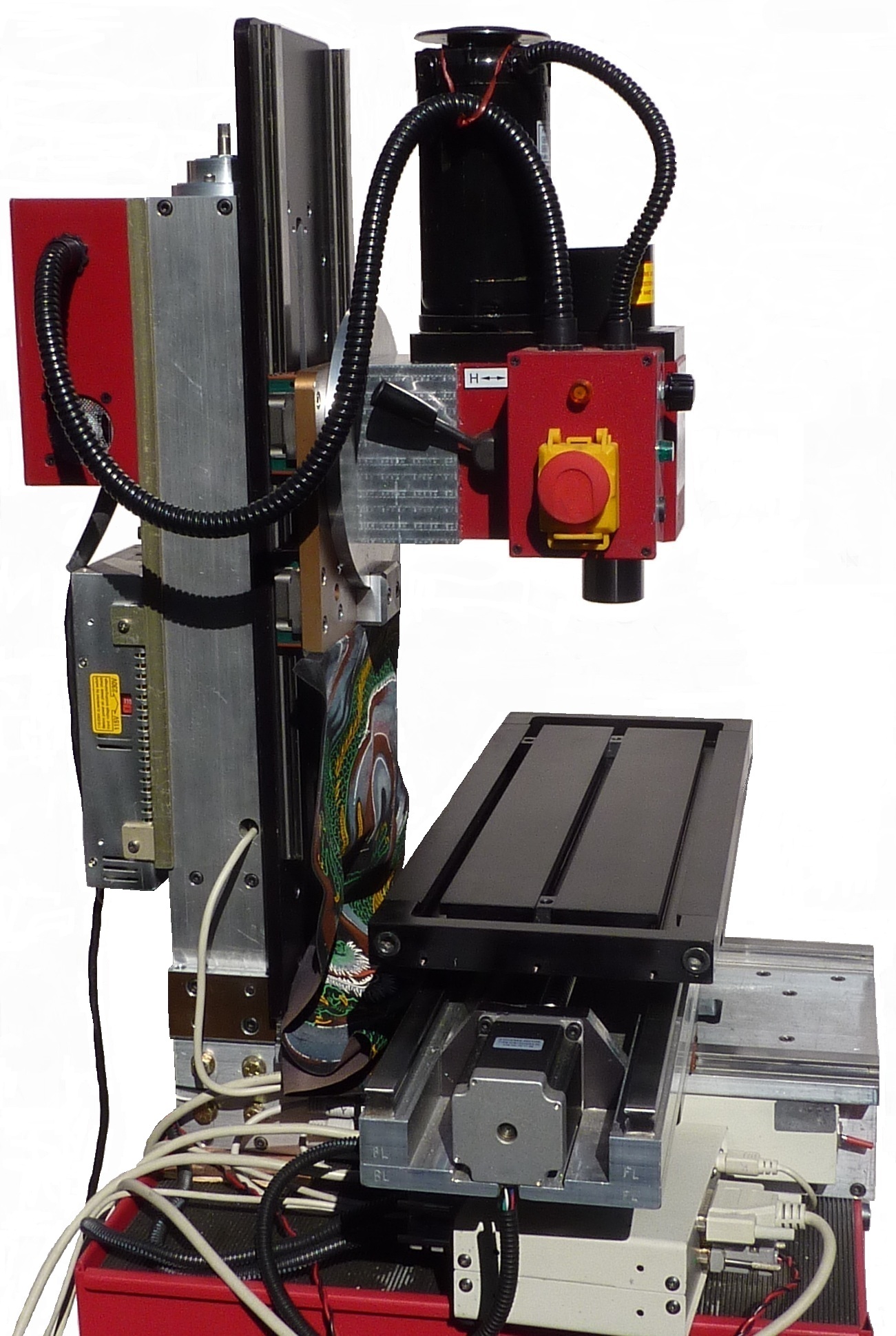

In the first photo I can’t quite make out what the “swirly modern-art” painting is:-

Is it a rare Thailand jungle bird’s head?

The painting is still there but also a whole load of hardware is on show:-

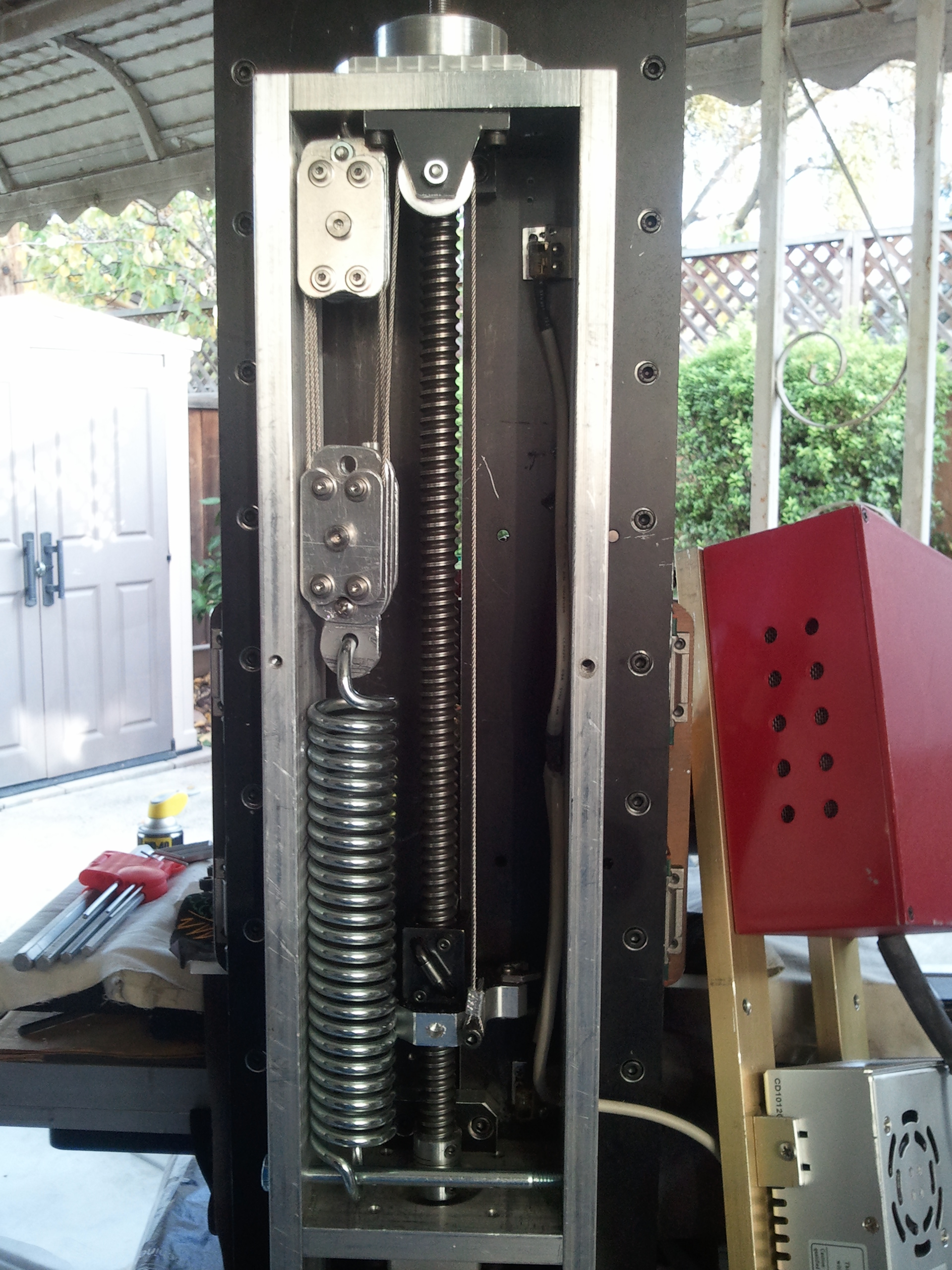

Very neat and clever hiding of the head counterbalance in the column:-

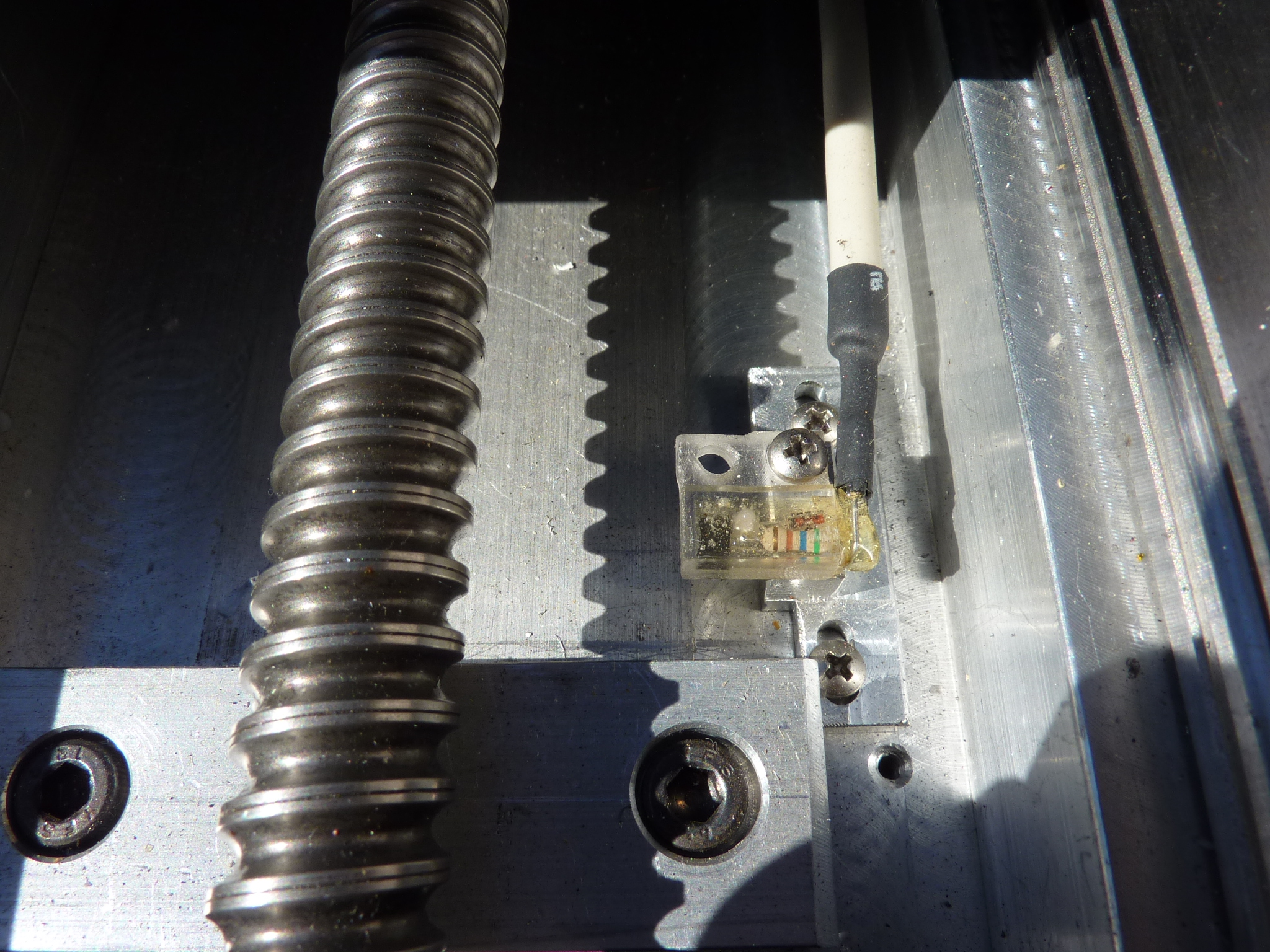

I thought this photo was to show the ball screw, but it’s to show the Hall effect sensor:-

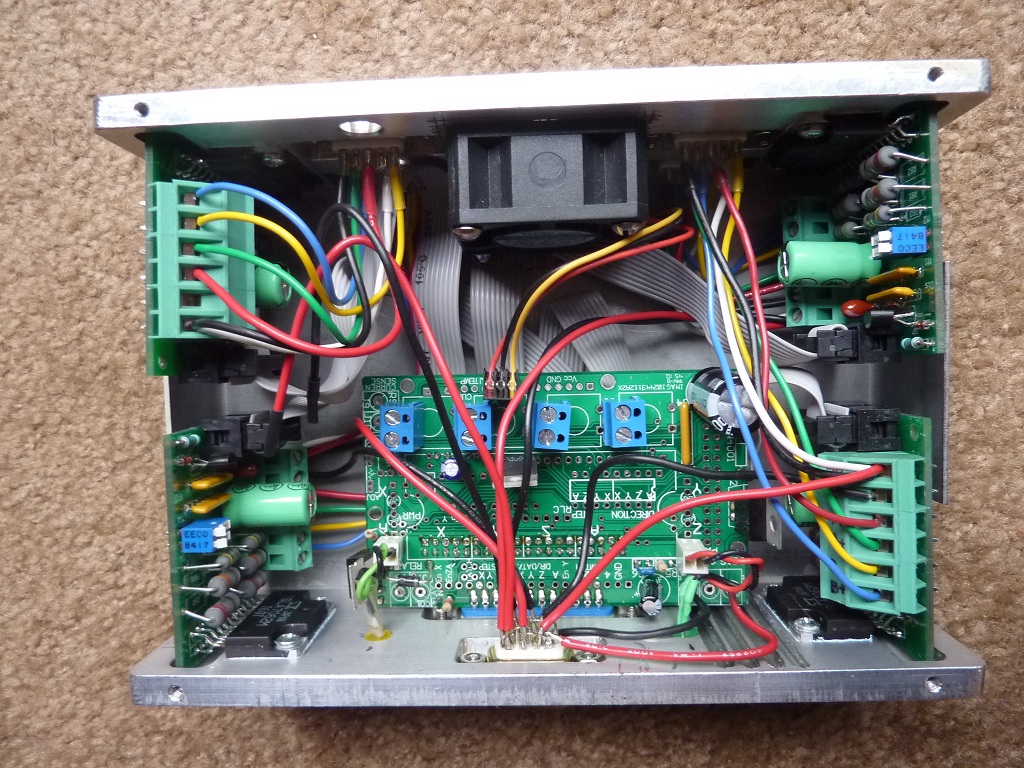

All those wires. Quick put the lid on!

Full Story “How I Built My CNC Milling Machine” Available As A Download

Mike has written a fascinating description of how he designed and constructed his DIY CNC milling machine and it covers all the hardware, the machine itself and the electronics. It’s is 15 pages long of text, photos and Mike’s design and construction sketches.

You can freely download this Booklet from this website as a .pdf file.

Further details of the Booklet and the download link for “How I Built My CNC Milling Machine” are on the “How I Built My CNC Mill – Free Plans” Page.

The Next Phase Of The DIY CNC Milling Machine – Testing It Out In Thailand

This is Mike’s closing paragraph:-

| “Now it’s on to the next phase: testing.I had hoped to have the time to fully test and check my newly created little toy before I needed to partially disassembled it and pack it up for shipping to Thailand, but I ran short of time.So at present time my mill sits in a box here in Thailand awaiting re-assembly.

I still need to fully check the mill for trueness, that is, if I were to mill out a square box, will it be a perfectly rectangular box with perfect 90° angles all around? How stiff is the final assembly? These are questions I still need answered.” |

Well, Mike we are all waiting to see how the testing went. An update would be very welcome when you have time, please.

DIY CNC Milling Machine Action Videos

Updated Added 24 January 2015

Well Mike has answered his own questions in the videos he has provided which show the CBC mill performing very well machining a plastic pill box lid under the CNC control of the Mach3 CNC software package.

The movies are too big to show here and also deserve their own page which has now been provided as “DIY CNC Milling Machine Action Videos“.

Other Pages In This Section

Thanks for the kind words Andrew. In my past “work-life” I was an electronics engineer, so putting in a few wires, circuit boards, and sensors is all very familiar ground for me. The new & challenging areas for me, are learning to make 3D CAD drawings, read those drawing files into a CAM program, which generates “G code”, and finally run the G code file on the “controller” software which controls the X Y Z axis on the mill.

Yes, there are days when I think I’m more than a little crazy,…then there are other days when I absolutely certain 🙂

Mike (in Nong Khae)

Mike,

I am really impressed that you took on such a project. CNC is terrifying enough if using a bought machine, never mind making one! I’ve never ventured near any projects with any wires attached as I am sure it would end up ripping my work to pieces!

I think I will continue fir some time with my manual machines, although CNC would come in handy for detailed work. Maybe one day ..

Regards,

Andrew