Details Of George’s Next Project – A Model Of The Horizontal Twin Cylinder Hydraulic Pumping Engine Originally Designed By Sir William Armstrong

A Fascinating Model And The Story Of the Men Behind It

George sent me a couple of photos of the kit for his next model – a twin cylinder steam engine. I thought this will be a quick exercise to put these photos on the website and add a a few notes to support the photos.

But it didn’t turn out like that. George didn’t send me much in the way of a narrative so I started to look on the Internet for a few words of description. Pretty soon I was pulled into a full-blown research project as the fascinating story behind the model began to unveil itself.

Here are some of the key strands (in no particular order) to the story that so fascinated me:-

- William George Armstrong, 1st Baron Armstrong, CB, FRS (26 November 1810 – 27 December 1900) – phenomenal man.

- The World’s Biggest Gun.

- National Waterways Museum, Ellesmere Port.

- The Tower of London’s steam-powered hydraulic bridge raising mechanism.

- Cotswold Heritage.

- Model Engineer.

- Anthony Mount.

Photographs Of George’s Kit of Parts for the Sir William Armstrong Horizontal Twin Cylinder Hydraulic Pumping Engine

The report on my research of the people behind this model and what the real-life engine was used for can wait a while, let’s take a look at the photos of the kit of parts that George sent to me:-

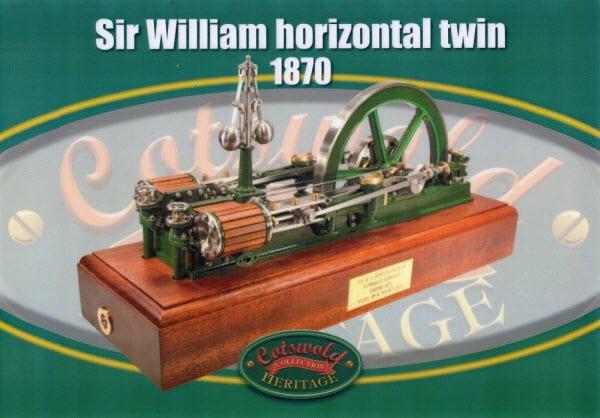

As you can see in the photo above it’s a comprehensive kit of parts and I tracked the supplier down to Cotswold Heritage.

Notice the artwork from the box in the background. I’ll show you a close up in a minute. First another photo of the model steam engine kit:-

The Cotswold Heritage Collection.

In the photo above you can see more clearly what is included in the kit of parts for the Sir William Armstrong Horizontal Twin Steam Engine Model from the Cotswold Heritage Collection.

Cotswold Heritage offer three kits and I’m not sure which kit George has but I’ll assuming (George will soon but me right in a comment below) that it’s Kit A containing:-

Large casting set including:

- Flywheel

- Cylinders

- Drive pulley

- Bed plate

- Sixteen detailed water jet cut parts

Together with:

- Externally machined hardwood base

- A comprehensive drawing pack.

Kit B is for forty high prevision bronze casting offering high levels of detail and “build time savings”.

And Kit C includes Governor components inc. machined gears, drive band and compression spring.

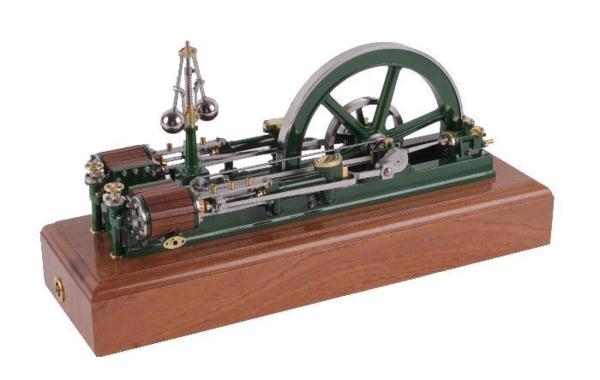

Now for some photos of what the finished model my look like beginning with the extract from the Cotswold Heritage literature mentioned above:-

That’s how Cotswold Heritage see the model being finished.

Bronze Medal Winning Model Engine

Here is a photo of an award-winning model finished by Mr J Wingate of Winchester and offered for sale at auction by Dreweatts of Bloomsbury:-

According to the Dreweatts of Bloomsbury description of the above model it was awarded a bronze medal at The Model Engineer Exhibition 2013. The Chief Judge being Mr Ivan Law.

The model sold for £3,200.

Original Prototype Of The Model

Engine At The National Waterways Museum, Ellesmere Port

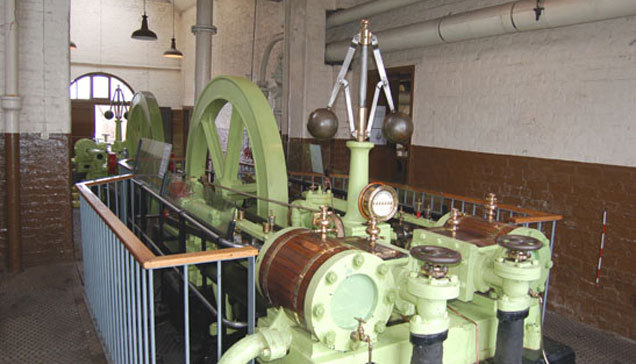

Both the text supporting the Dreweatts description of the model and the Cotswold Heritage website also suggests that the full sized original of the model powered the hydraulic cranes and capstans throughout the dock at Ellesmere Port. The prototype of this engine can been seen at The National Waterways Museum, Ellesmere Port.

Here is a photo of that engine:-

However reading the entry for Sir William George Armstrong, 1st Baron Armstrong, CB, FRS on Wikipedia

suggests that the original engine powered the hydraulic mechanisms that lifted the bridges of London’s Tower Bridge.

To quote from Wikipedia “Elswick built and installed the steam-driven pumping engines, hydraulic accumulators and hydraulic pumping engines to operate London’s Tower Bridge”. Elswick refers to the company “Sir W.G. Armstrong & Company” formed by a merger of W.G. Armstrong & Company and Elswick Ordnance Company.

The Steam Pumping Engines at London’s Tower Bridge

I discovered details of these engines again on Wikipedia but under the entry “Tower_Bridge“.

Again, to quote Wikipedia “The original raising mechanism was powered by pressurised water stored in several hydraulic accumulators. The system was designed and installed by Hamilton Owen Rendel while working for Sir W. G. Armstrong Mitchell & Company of Newcastle upon Tyne.”

This clearly suggests that the Tower Bridge steam pumping engines were a Sir William Armstrong (or at least his company’s) design.

Here is a photo of the London Bridge steam pumping engine:-

I think you’ll agree that it looks similar to the model depicted by the Cotswold Heritage kit. I can see, however, that the crank is a disc crank whereas the Cotswold Heritage engine has a ‘pear-shaped’ crank. (Somebody please give me the correct technical term for this type of crank.)

Also the London Bridge engine shows a shaft dropping vertically from the crank presumably to power the hydraulic pump below whereas the Cotswold Heritage design has horizontal pumps.

There is another steam driven hydraulic pumping engine at Tower Bridge in London, this one being a ‘standby’. Here is a photo of it:-

Clearly this isn’t a Sir William Armstrong engine but it does bear resemblance with the other engines, although again it has a disc crank and I can’t see the pump connecting rods.

You can see from the information above that I was unsure which engine was the prototype.

Model Engineer And Anthony Mount

I have a few years collection of Model Engineer Magazine which I have been re-reading and collating. I vaguely remembered seeing an engine like the one to be modeled by George in the magazines but I had no idea which one and I wasn’t going to plough through all of them to look for it.

Model Engineer Indexes

I do however have a set of Model Engineer indexes downloaded from the Internet from the very first edition in 1898 to Volume 212 of 2014.

In there I located the introductory article “Armstrong’s Hydraulic Pumping Engine” by Anthony Mount in the 2011 issue Volume 207, Issue 4410.

I had the 2011 set of magazines but guess what? Issue 4410 was the only one missing!

Model Engineer Forum

So it was over to the Forum on Model Engineer website where I made this Post:-

Title: Original Of Sir William Armstrong Steam Engine

Description: Where is the original of this model by Anthony Mount?

“A friend of mine is making the Sir William Armstrong Steam Engine Horizontal Steam Twin Engine Kit from Cotswold Heritage and I’m trying to find out for him the original engine upon which the model was based.

The model was designed by Anthony Mount and was introduced in Model Engineer Magazine 2011, Volume 207, Issue 4410, Page 234. Unfortunately this is one missing from my collection!

Research on the Internet throws up two possibilities, either the Hydraulic Pumping Engine that powered the hydraulic systems at Tower Bridge London or the engine displayed on the Canal & river trust website and stated to have “supplied the power for hydraulic cranes and capstans throughout the dock at Ellesmere Port.”

These are relevant websites:-

http://en.wikipedia.org/wiki/Tower_Bridge

https://canalrivertrust.org.uk/national-waterways-museum/exploring-the-museum/the-pump-house

Only one of these can be the inspiration for the model, but which one?”

Reply From The Forum

It wasn’t long before I received this reply from a Moderator, Jason B:-

“Its based on the pair at the Boat Museum, National Waterways Museum, Ellsmere Port.

There is another thread on this engine on teh forum if you have not seen it yet.”

Mystery Solved

So now I knew the original prototype for the Sir William Armstrong Steam Engine model described by Anthony Mount in the Model Engineer magazine in 2011 was based on the full sized engine at the Boat Museum, National Waterways Museum, Ellsmere Port that use to power the hydraulic cranes and capstans in the port at Ellsmere.

Other Forum Thread

I took a look at the other Thread on the Model Engineer Forum and it’s the one titled “Sir William Armstrong problems”. This Thread discusses some problems with the castings supplied by Cotswold Heritage, such as:-

- Lost-wax (Kit B) castings undersized and ‘not fit for purpose’.

- Kit A water-cut parts undersized.

- Kit A Base Plate casting issues.

No doubt George has already seen this Thread, if not he is now alerted to it.

With that out of the way let me show you a little of what I discovered about Sir William Armstrong and ending with his Big Gun.

Sir William George Armstrong, 1st Baron Armstrong, CB, FRS (26 November 1810 – 27 December 1900)

Without wishing to paraphrase the Wikipedia entry for Sir William George Armstrong (but probably doing so) here are some of the facts about this outstanding man.

Key points:-

- Born at Newcastle upon Tyne in 1810.

- After five years in London studying law returned to Newcastle in 1833 to became a partner in Donkin’s business and worked for eleven years as a solicitor.

- Developed a piston engine powered by water suitable for driving a hydraulic crane.

- Elected a Fellow of the Royal Society in 1846.

- Installed the first hydraulic crane at the Quayside followed by three more.

- Started W.G. Armstrong & Company which received orders for hydraulic cranes from Edinburgh and Northern Railways and from Liverpool Docks, as well as for hydraulic machinery for dock gates in Grimsby.

- In 1850 the company produced 45 cranes and two years later, 75. It averaged 100 cranes per year for the rest of the century.

- The company soon branched out into bridge building, one of the first orders being for the Inverness Bridge, completed in 1855.

- Invented the hydraulic accumulator in 1850-1

- In 1854, during the Crimean War, Armstrong read about the difficulties the British Army experienced in manoeuvring its heavy field guns. Armstrong built an 18-pounder gun that was declared to be superior to all its rivals.

- Armstrong surrendered the patent for the gun to the British government and was created a Knight Bachelor and in 1859 was presented to Queen Victoria. Armstrong became employed as Engineer of Rifled Ordnance to the War Department.

- In 1894, Elswick built and installed the steam-driven pumping engines, hydraulic accumulators and hydraulic pumping engines to operate London’s Tower Bridge.

- Armstrong advocated the use of renewable energy. Stating that coal “was used wastefully and extravagantly in all its applications”, he predicted in 1863 that England would cease to produce coal within two centuries.

- In 1887 he was raised to the peerage as Baron Armstrong, of Cragside in the County of Northumberland becoming the first engineer – and, indeed, the first scientist – to join the House of Lords.

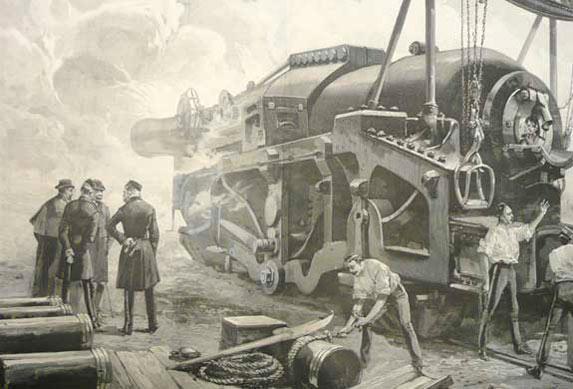

William Armstrong’s 111-Ton ‘Monster’ Gun

A rare picture has been unearthed portraying William Armstrong’s 111-ton “monster” gun. Posted on 11 June 1887 in the Illustrated London News, the picture demonstrates the testing of the weapon – then the biggest firearm in the world – at Woolwich Arsenal in southeast London.

Constructed at the Elswick Works of Sir W. G. Armstrong, Mitchell & Co. of Newcastle upon Tyne, it was designed for arming the most modern warships.

The gun’s shells were 16.25in (413 mm) diameter and a the gun’s total length was 43ft 8in (13.3 m). It’s 1,800lb (816 kg) shells blasted from the barrel at a velocity of 2,020ft per second (616 m/sec), and could bore into wrought iron to a depth of 30.6in (777 mm) from 1,000 yards (914 m) away. The gun had an effective range of 8 miles (12.8 km).

And with that photo I’ll bring this page to an end.

Please add your comments below – I’m sure there are many things to say.

Good morning Alan

I had forgotten that I had sent the photos to you without any narrative.

First of all the photo shows parts supplied by Cotswold Heritage. But I am thinking of changing much if not all of the bright mild steel components to stainless steel. Or cast iron. Which is the reason there is so much bar stock in the photograph.

As you have mentioned in past posts the rust bug is alive and well in Thailand.

I have read a few reports about the casting being undersize. I am sure when I get time to start the project I will find out.

It is a good looking engine but will try my skills. Most of the screw fixings are in the 8 and 10 BA range. And the size of some of the castings are very small. The cranks are cut from mild steel but I hope to use the cast iron bar to replace them.

The research you have completed on the engine and its designer was very impressive.

A model of the big gun would look very impressive.

Regards George

Hi George, it’s evening here now.

Not sending the narrative was a good thing. It made me do the research into the model and Sir William Armstrong which I found both enjoyable and fascinating.

As to the rust bug I have just painted some bright mild steel parts with ‘clear paint’. It’s readily available here in Thailand and it looks really good as in you can’t see it! I’ll write an article about it but I intend to paint all the non-contact surfaces on my tools and models with it. Contact surfaces will get the ACF50 treatment.

I gave up on small models as you know – I just can’t see those small parts let alone trying to make/manipulate them. I did make a Gauge 1 Bogie for a Black Five Loco based on LBSC’s 3 1/4″ gauge Doris many years ago. I still have it here and when I look at it’s quite exquisite in it’s tiny detail even if I say so myself. I have some good photos of and will upload it to the website sometime.

My thoughts about a model of the gun are the same as yours. The picture of the gun really captures the atmosphere, doesn’t it?

I also thought about some model cranes and etc driven by the hydraulic pumps from the horizontal twin cylinder horizontal steam engine steam engine. I have seen a photo of a model William Armstrong hydraulic crane and can post it if anyone is interested. But I have so many other models to make and finish off that will be just a ‘dreaming about it’ project.

Thanks for the comment.

Alan