How To Make A DIY Steel Work Bench for 6,600 Bhat In Thailand

Mike lives in in Nong Khae/Saraburi in Thailand and he has already provided full details of a fully functional DIY CNC milling machine that he designed and constructed himself.

Now he describes his approach to designing and building a homemade steel workbench for his workshop in Thailand.

Yet another demonstration that Model Engineering and home amateur machinists and metalworking hobbies are flourishing here in Thailand.

Here is the article about how to build a steel workbench for your home workshop for 6,600 Baht.

Instructions And Plans To Make Your Own Steel Work Bench

I needed a workbench, but should I buy, or build my own? I quickly discovered that you can’t simply walk into HomePro or Thai Wasadu and buy one, and there are no Harbor Freight or similar stores here in Thailand.

Seems that Thailand has only a few stores that specialize in workshop items and the few benches I was able to find were all priced far above what I was willing to pay, so I decided to build my own.

The list of hobbies I enjoy is a rather long one, everything from wood working to electronics to machining and assembling metal parts, which meant the bench I needed must be multipurpose and didn’t need to be too heavy duty; as long as it could comfortably carry perhaps 300 lbs (136 Kg) it would be quite adequate.

A steel tube frame with a heavy wood top should do nicely, and for added utility, include a few drawers, a shelf on the bottom rear side, and locking casters on all four legs.

1½” x 1½” x 2.3 mm square steel tube, welded at all junctions should make a good sturdy frame.

I give Alan a lot of credit for taking up the challenge of learning to weld, as it’s one skill I’ve tried several times over the years and have never been very good at.

Now, I’ve known a few professional welders in my past and they’ve all told me that learning to weld thin pieces of metal is much, much harder than welding thick pieces, so, since the bench would require welding “thin wall” tube, I knew I didn’t possess the level of skill needed.

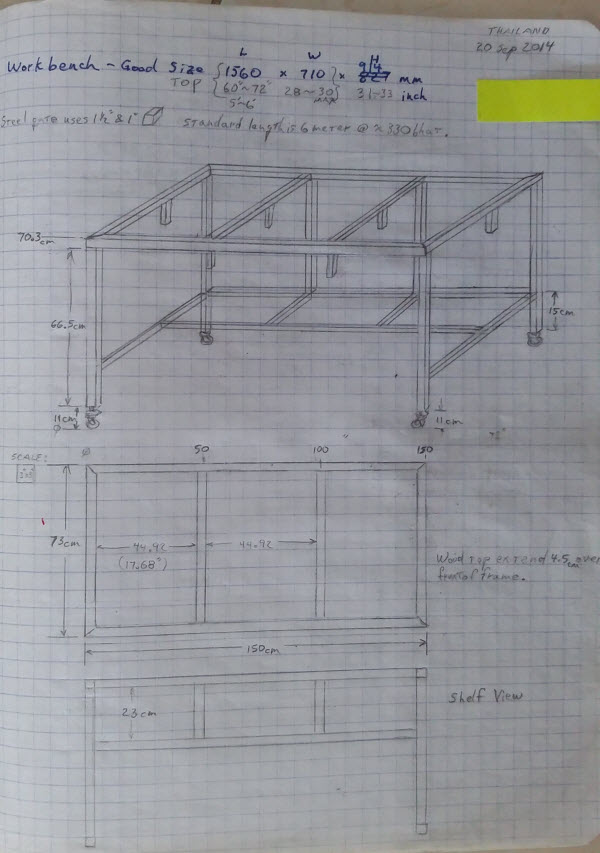

Fortunately for me, Thailand has lots of skilled welders that charge a very reasonable rate. I took the following sketches to a local welding shop; the total price for the frame was 3,500 Baht, which included the cost of the metal:-

Another plan of the steel workbench below:-

Here’s a close-up look at the welds. Notice the weld bead is relatively uniform and smooth.

Good quality welds, showing good metal flow.

The below photo shows the completed frame which measures 150 long x 73 wide x 70 cm high.

The frame needed a thorough cleaning with soap & water before painting could begin; I used two spray cans each, of acrylic lacquer for both the primer and finish coats.

The Wooden Work Surface of the Work Bench

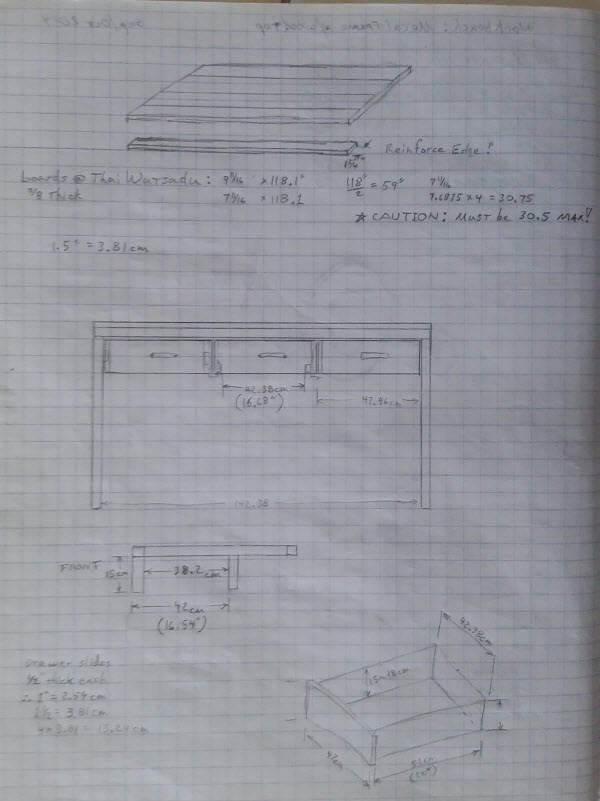

The wood top is made from two 20 cm x 3 meter x 25 mm boards purchased from Thai Wasadu.

The two boards were each cut in half, giving the desired 150 cm length. All four boards were then glued together along their long edges to get the desired width. I was unable to find proper wood clamps, so I used some nylon tie-down straps with ratcheting ends to tighten and hold the boards in place while the glue dried.

Work Surface Materials And Durability

I’m not at all certain what type of wood the boards are made from; my wife thinks they could be Rubber tree.

Comparing pictures I found using Google Images, the wood certainly looks like rubber tree and after cutting, sanding, and planning the boards, they are obviously some type of hardwood.

Each purchased board is made up of many smaller pieces, all of which are glued together and then finished to a smooth surface and the exact final size.

Very little sanding was needed between coats of polyurethane; four coats on top and three coats on the bottom.

Time will reveal how durable the wood top proves to be, but if it proves too soft, I can always apply a 1/8” sheet of steel or aluminum to the top surface at some future time.

Alternative Ways To Attach The Wood Work Top To The Steel Workbench Frame.

There are many different methods I could have used to attach the wood top to the metal frame; the simplest technique would have been to simply drill holes through the metal frame and use screws that go all the way through the 1½” tube and into the bottom side of the wood top.

But I wanted to have a bit more fun with it, so I chose a somewhat more complex method.

Four wood blocks were cut from a length of 2 x 4 (which is actually 1½” x 3½”). I also used a scrap piece of ¼” Lexan I had laying around the shop.

After painting the wood blocks white, I drilled 5 holes in each of them to match the hole pattern which I had already drilled into the Lexan plates.

Each block & Lexan plate was mounted onto the bottom of the wood top, one in each corner, as shown in the following picture.

For those who have no experience with Lexan, I assure you that it’s incredibly tough stuff; it doesn’t break and doesn’t easily bend.

A Workbench On Castor Wheels!

I realize that rolling workbenches are not for everyone, but I personally love being able to easily roll my bench from one side of the shop to the other, or spin the entire table to provide easy access to the backside.

The casters I used were purchased from Thai Wasadu and have proven perfect for the task; the locking mechanism not only prevents the wheels from rolling, but also locks the rotating spindle such that when all four wheels are locked, the table is very stable.

I’ve already used the table for some light hand sawing and filing and I’m quite satisfied with how stable the bench is with the wheels locked; the rubber circumference on these wheels really sticks to the high gloss tile in my shop.

Below is a view of the back side of the bench showing how I’ve already put the shelf to use.

Above, Back side of workbench.

The shelf is not rigidly attached to the frame but instead has two small wood blocks glued to the bottom surface of each front corner which fit into the corners of the metal frame and, along with the cut-out notches for the frame, prevent the shelf from slipping around. The photo below shows one of the little plywood blocks glued onto the bottom of the shelf.

The drawers and shelf were all made from a single 4’ x 8’ sheet of 3 ply 8 mm plywood.

The drawer slides are 20” long and purchased from, you guessed it, Thai Wasadu.

Each drawer measures approx. 16½” W x 20” L x 6” D.

All the plywood pieces were glued and nailed into position, then painted. I typically prefer to clear coat wood surfaces to show the wood’s grain, but the plywood I used was of such low quality that I decided that cover the surface with paint.

Below is a front view of the nearly finished workbench; with casters: 59¼ L” x 30¼ W” x 33½ H”.

I’m still looking for proper drawer “fronts” to give the drawers and bench that “finished” look. At least for now, I have a very functional workbench.

Cost Details And BOQ For Building A Steel Framed Work Bench In Thailand

| Bill of Materials | Baht |

| Metal frame welded assembly | 3,500 |

| Wood for top (340 Baht / board) | 680 |

| Drawer Slides (300 Baht each set) | 900 |

| 4’ x 8’ x 8mm plywood, (Drawer & Shelf) | 480 |

| Casters with locks (150 each) | 600 |

| Polyurethane & Paint | 270 |

| Misc hardware (screws, nails, glue) | 150 |

| Total | 6,580 |

A Perfectionist’s Work Bench?

A Comment by Alan

As you can see from the above article Mike is very careful and thoughtful when creating his projects. He has an eye for detail and want’s to achieve a high level of finish and appearance.

In contrast my workbenches are functional and that’s all. In fact one of my ‘functional’ workbenches fell to pieces when I tried to move it!

That particular workbench was similar to Mike’s in that it had a frame of rectangular steel tube. It was (as I thought) welded using oxy/propane and a steel top welded on. I never painted it.

It’s worth comparing my rough and (not always) ready workbenches and shelves with Mike’s masterpieces.

Also Pete is building a workbench to carry a heavy lathe. It’s interesting to read Pete’s approach also.

New December 2014 – Modular Work Bench Fixture Plates

To allow the easy attachment and removal of bench vice, bench grinder, etc to the Steel Workbench described above, Mike has now designed and made a set of workbench modular Fixture Plates.

Mike describes the fixture plates and shows photos of how to make and use then on the new Workbench Fixture Plates Page.

Hi Everyone.

I’m another who found this article via a Google search. I happen also to live in Thailand and, as I approach retirement, want to get back into my schoolboy model engineering, although at the current rate my darling Wifey is constructing palaces for her chickens, geese, guinea fowl and other assorted ‘pets’ I may never actually be able to retire. At least the eggs are good and our 1.5 Rai (1/2 acre) garden produces wonderful tropical fruit 😛

My real job is as a Consultant Engineer (a fancy name for “Person to blame when it goes wrong”) on major transport infrastructure projects (BTS and MRT lines for those in Bangkok).

We live in Chiang Rak Yai, about 40km north of Bangkok, been in Thailand since 2004, met the lovely lady in a Thai restaurant in Rome (yes Italy).

Keep it up

Dave C.

Hi all, great plans. Need to build a bench for my shed. Your bench was no.1 result in a google image search for “steel work bench designs”. (picture says 1000 words!) Didn’t have to look further! Design is super combines all elements any keen hobbyist would require! many thanks from a wee shed in Northern Ireland- keep up the good work!

Hi Alistair and many thanks for your comment.

That steel bench design was not mine by the way but was designed and built by Mike in Nong Khae, Saraburi Thailand.

My own first steel bench I built in Thailand fell apart when I tried to move it!

I had ‘welded’ it together using a small oxy-propane brazing torch. I didn’t have an electric welder at the time. When I re-built it I used manual metal arc welding (MMA) – AKA “stick welding”.

But George, you use water cut parts in your models, not chain drilled hacksawed and filed as I do!

And you use DRO on the milling machine instead of marking out and centre-popping.

You’re not as old fashioned as you make out to be. I bet you even use a calculator instead of log tables.

Hi Andrew,

A few days ago I had to re-build one of my own home-made benches. It was located out in the garden in a very sunny place ie very hot!

My wife asked why I didn’t move the bench to a cooler place under the shade. When I said because it’s too heavy and she replied that would help me move it I couldn’t refuse.

We tried lifting the bench but we could only manage to move a foot because of the weight. So I decided to ‘over-end’ it. Over it went and fell to pieces!

All those ugly gas ‘welds’ were not as strong as I thought.

(See the original gas-welded bench story on the Making A Steel Work Bench page)

So I had to grind away the remnants of the gas welds and re-weld using the electric arc welder.

Good morning Mike

Looks to me you have found a new profession and business opportunity. The finished bench looks very well designed and well made. Will you be making a matching high stool to complement the bench? I have found that some of the small fine work I have to file and polish is best done while seated. Might have something to do with my old age!

Are you going to fit a heavy duty vice to the bench? I have drilled holes in my bench top for the bending and other tools that need to be fixed down. But I do not want on the bench all of the time. As I find a clear bench is easier to work on and keep clean.

Once again well done

Regards George Hill

Hello George,

I had not considered making my own high stool,…I’m hoping that I can find something suitable in one those little wood furniture stores that seem to be all over Thailand. For the moment, I’m using an office chair I brought with me during my move from the US,…it’s just high enough on it’s highest setting.

I completely agree with your “clear table” philosophy and to that end I will cut several pieces of wood boards from the same size board I made the table top from (8″ x 10″ x 1″). Each board will be used to mount things like a heavy 5″ vise and a grinder. Each board will be the same size and have matching holes pre-drilled that match up to holes in the table. The holes in the table will have metal threaded inserts which will make changing out the vise for the grinder quick, easy, and repeatable without damaging the table top. I’ll send Alan an update of this when I complete it.

Keep making metal (and wood) chips,

Mike

Good afternoon Mike

One comment on the note book added design. No use of CAD or other high tech just paper and a pencil. I assumed I was the only guy still doing things that way. For the more accurate stuff I still use the old Tee square my farther used at night school over eighty years ago.

George