Philip Has Made This Amazing CNC Controlled Plasma Cutting Machine In His Own Model Engineering Workshop Here In Thailand

Not Simply Amazing – It’s Astonishing

In my view this is not simply amazing – it’s astonishing. Why do I say this?

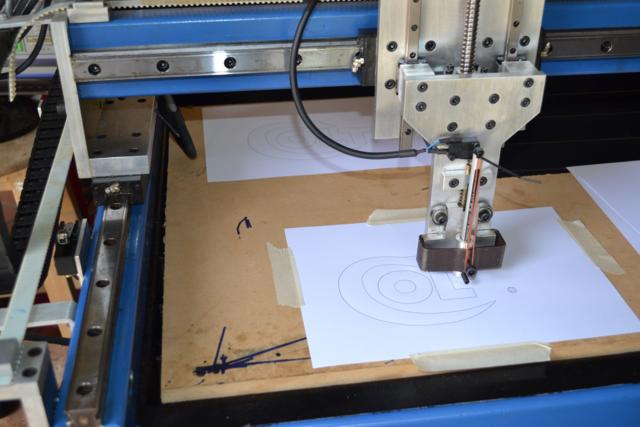

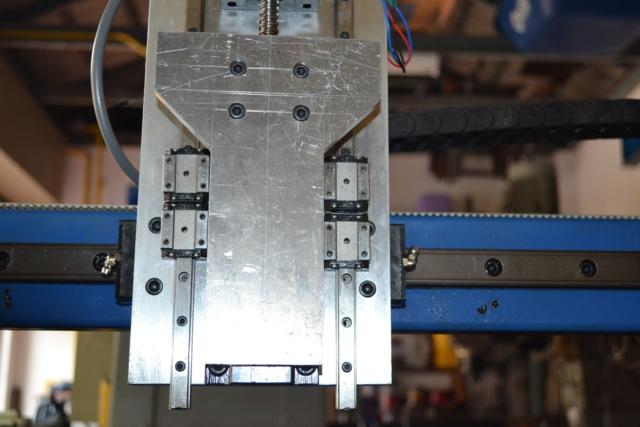

Firstly because Philip made no drawings. Just look at the size and complexity of this machine in the photos below and I think you’ll agree that this is a fantastic accomplishment.

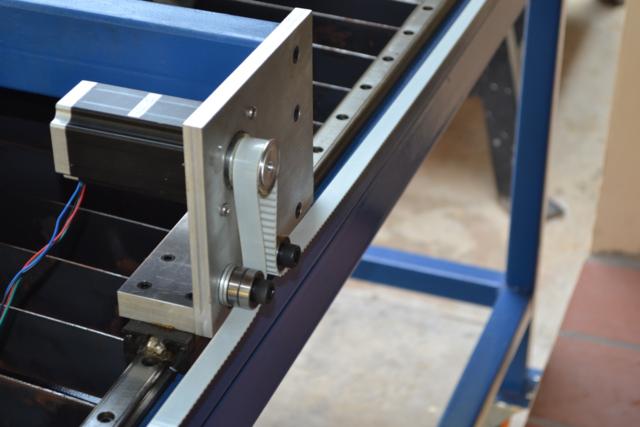

Secondly because Philip had to source all those CNC components, the stepper motors, the controllers, linear bearings the drive belts etc. Whether he bought them in Thailand or imported them I don’t know, but it’s a something I’m going to ask him.

Notes By Philip On His CNC Plasma Cutting Machine

Because I think you would like to see the photos straight away I have put Phillip’s notes and commentary at the bottom of the page.

Photos Of The CNC Plasma Cutting Machine Made In Thailand In A Home Workshop

Important Note: There are fifteen high-definition photos below showing the details of the CNC plasma cutting machine so this page may be slow to load, particularly on smartphones and the like.

Notes By Philip On His CNC Plasma Cutting Machine

Well, I received some emails from Philip so to give you the best information, I’ll simply post them below.

| Email Dated Dec 19, 2016

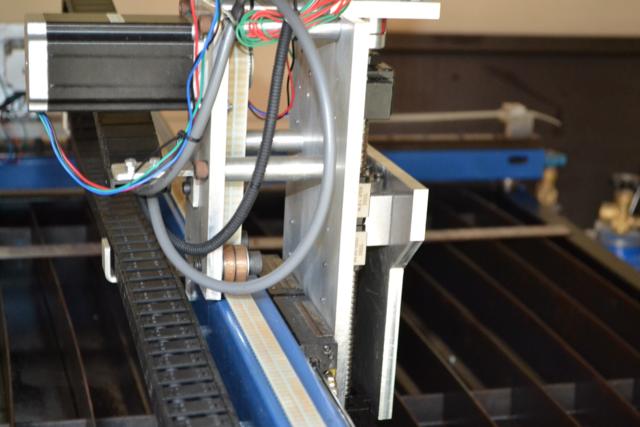

Hi Alan, You will note one major error with the build, this being that the table is to high. I guess this is the result of not preparing drawings. I am reluctant to reduce its height as it is good and square. The table working area is 4′ x 4′ for the majority of the work I will be doing I should be able to lift a sheet of 4 x 4 plate onto the table without to much trouble. The initial wiring is messy as you will see in the photos, I did change most of it to shielded cable as I was seeing interruptions in the program as the stepper motors were operating, so it looks a little better now that its finished. The table is ready to go now, all that is left is for me to make the decision on what make of Plasma machine to purchase, it will probably be one of the Thia supplied machines either Welcut of Longwell. The American made machines are also available but they are very expensive. As for the programing I have been using trail versions of Sheet Cam for the nesting of parts and MACH3 for setting the cutter path, these I will purchase as soon as I can, but I am having difficulty purchasing them without having to pay UK VAT, despite the fact that the programs will be used only in Thailand. The Colt logo was just vector drawing I found on the internet, I am not sure of its origin, I thought it may be American (beer possibly). Over the coming weeks I will try to send some information that you can add to the Model Engineering website, this will be of interest to anyone looking for used machines, tooling (end mills, drills carbide inserts etc.) and measuring instruments. I will try to upload a clip of the shaper in action on Youtube, once done I will share the link. The file is to large to email. Well I will be spending Christmas and New Year working in Myanmar, so it will be a quiet one for me. Merry Christmas to you and the Model Engineering community. I have to agree that there is a wealth of expat knowledge in Thailand, it is just a shame that we cannot all share our expertise. I have met a number of Thais who run their own workshops on a commercial basis, who are also interested in one off projects, also having the time to talk to us and sharing ideas and knowledge. My past few weeks has been spent setting up a 600mm shaper machine, all up and running now. Quite a challenge getting the two tonne machine into the workshop up an 8″ step but my wife and I managed with a little engineering and brute force. The plasma CNC has taken a backseat at the moment, I have not forgotten to put together some pics of the build. I will be back in work in the coming week so will put the photos together and a small clip of the shaper in action. Merry Christmas to you and the Model Engineering community. Regards, |

Philip has previously commented on the website with information about sources (suppliers) of workshop tools in Thailand:-

https://modelengineeringinthailand.com/resources/tools/tools-suppliers/#comment-2071

Update January 2017

In response to requests from myself and another reader, Mike, Philip has provided the following additional information for which I am very grateful:-

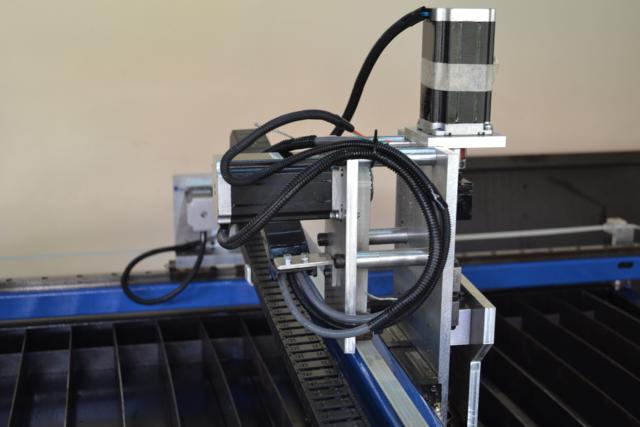

| Hi Alan/Mike

Firstly I would like to thank Alan for his time and patience in posting the photos and text on the Model Engineering website. Alan, Thank you for your comments and questions. I have followed a number of Plasma table builds on “youtube” rightly or wrongly I thought I could do that, so started the trolling through web sites looking for ideas and equipment. The only criteria I had to work to was the size of my workshop (home shop), so I decided at the time that my machine should be mobile to some extent and not too heavy. My decision to use cam gears and belts was primarily to save on weight and to minimise maintenance. As you know cam gears and belt drives provide smooth operation with little or no backlash, in addition these are readily available in Thailand. The stepper motors are “NEMA 23” these are driven by HYQD20-5700 controllers. The breakout board is a five axis type. Power is supplied by a 500w 36v power unit, these I purchased from a company on Aliexpress. The machine is for home use only so I hope the components will stand-up to a little use at least. If not they are easily available as individual components. Again all available in Thailand but far more expensive and being of the same quality. My first job when I return home is to upgrade the power supply to the workshop, this will allow me to comfortably plug in a plasma machine without worrying about undersized cable etc. Once that is complete I will purchase the plasma machine, so it will be either a “Welcut 60” or a “Longwell cut-100”. I have been putting the purchase off until the power supply is uprated. Once again thank you for the interest, and other questions and I will be happy to answer them. Well I must get back to work, wishing Model Engineering and all its members a very Happy New Year. Phil. |

Thanks for the update Phil, and again, congratulations on a very well thought-out & clean build. Not that you seem like you need the help, but there’s a wealth of information on all manner of CNC machines at http://www.cnczone.com/, including a forum on plasm-EDM-Water Jet machines, http://www.cnczone.com/forums/cnc-plasma-edm-waterjet-machines/

BTW, You didn’t mention what voltage those NEMA steppers are rated for, I trust it’s somewhere around 3 to 6 volts max.

Anxiously waiting to see your beast in action,

Mike (now living in Rayong)

Contrary to popular belief Thailand is not a manual labor country, there are many CNC shops big and small. One central Bangna one is http://www.cncbro.com/catalog/ there are dozens on the road to Ayutthaya, Rama 2 and on the Bangkok-Chonburi Road.

Thanks for the comment Mike.

The sourcing of the CNC components (stepper motors, drives, controllers etc) was a question I was going to ask.

PCAM in Thailand sell stepper motors, controllers, ball screws and other CNC components as well s complete CNC and manual lathes and milling machines.

http://modelengineeringinthailand.com/resources/tools/tools-suppliers/pcam-precision-cnc-machinery/

Alan

That’s truly some great work Philip,… congratulations on a superb build !! I especially like your use of casters, as they greatly simplify moving the machine about the shop, or even to an outside location.

I am curious as to why you chose to use cogged belts instead of ball-screws on the X & Y axis,…costs? weight? Greater level of accuracy & rigidity of ball-screws vs belts simply not needed on a plasma torch?

What stepper controllers are you using?

Were you able to purchase the automation parts locally or did you buy them via eBay as I did?

I’m looking forward to seeing your machine in action 🙂