Part 2 – Running On Steam

In Part 1 I introduced the model steam plant I was making with my son, Alex, as a short holiday project.

Now, a good few weeks and a lot of work later, it’s running on steam and there’s a video here. Make sure to watch the pressure gauge in the top left!

General Comments on the Diorama

Burner Undersized

If you watched the boiler pressure gause in the above vide you’ll have seen how quickly the boiler pressure fell. Clearly the gas-fired burner (that came with the boiler is either a) undersized of b) not set up correctly. I’ve done quite a bit of investigating this and will report later. (Please join the Announcement List to be advised when I post the results.)

Other Coments

It’s a lot more advanced than the previous video when the engines were simply running on compressed air but this is still only a first stage – to get the engines running on steam.

There is a lot more planned for the future, like,

- More detail to the engines, pipework and plant generally, like,

- Cylinder Drain Cocks

- Better arrangement of displacement lubricators

- Thermal insulation (cladding) to the steam pipes

- More steam pipe supports

- Proper feed-water heater/condenser to rplace that vertical ‘hot well’ you see in the video

- Mechanical feed pump (See below)

- Cold water storage tank on a tower gravity feeding the ground level tank seem in the video

- Additional gas fired burner to the boiler – to be replaced later with a conversion to coal firing, then,

- Coal storage bunkers and a converyour velt to supply coal to the boiler

- And so on…

Steam and Water System Schematic

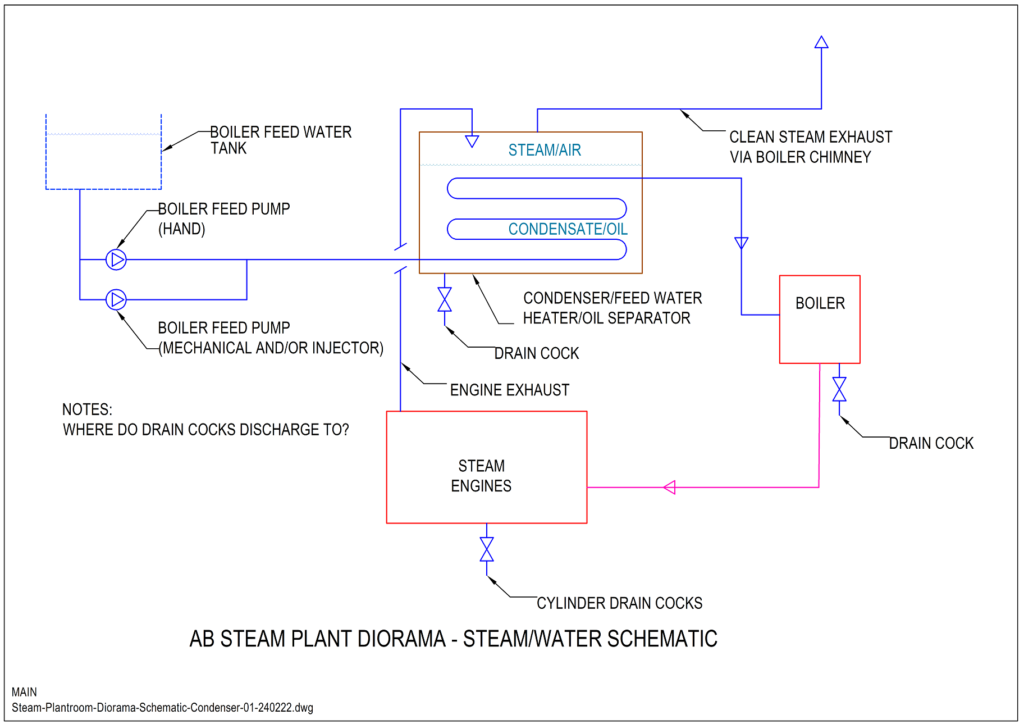

Here is a simplified schematic diagram showing what I’m currently planning for the final steam and water system for the steam plant diorama:-

Mechanical Feedwater Pump

This is my response to a friend when discussing this diorama and his experience running his own engines:-

Note your comments on the large amount of condensate produced potentially.

This ties in with my calcs for condensate rate and Keith Appleton’s (Youtube) comment that he is ‘continuously working the hand feed pump’ to get water into the boiler.

I figured out that for my two engines (1″ and 5/8″ bore) running at ‘modest’ speed I’d need 5.6 l/hour of boiler feed water. (= condensate)

With my hand feed pump of 3/8″ bore I’d be needing one stroke per second!

Hence a mechanical feed pump is required. Ditto condensate pump.

Ideas For The Mechanical Feedwater Pump

Idea 1

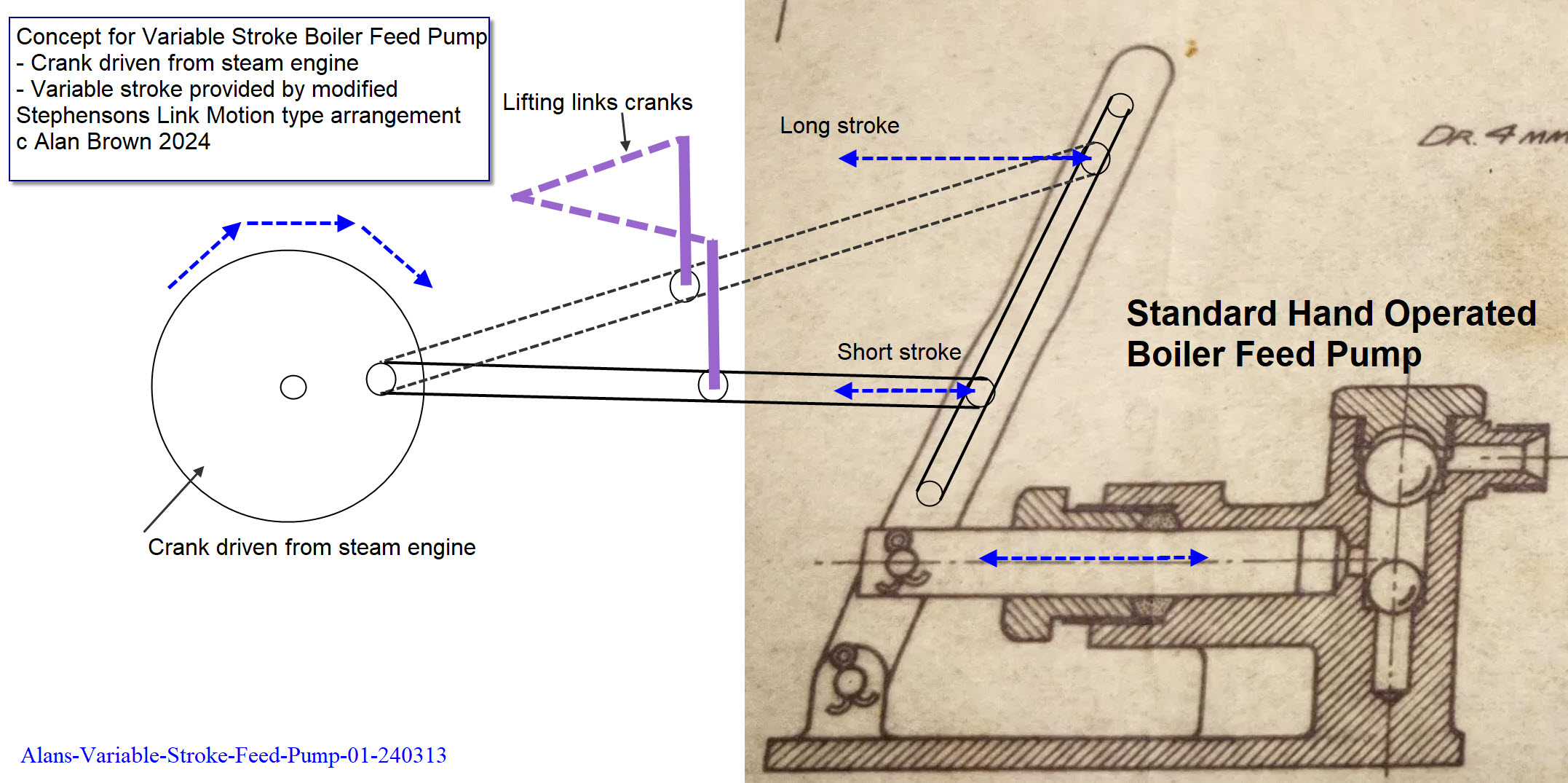

This is a sketch I sent to my friend as a preliminary idea for a feedwater pump:-

And here are my answers in reponse to his question “”Why the complex water feed pump?”:-

Idea 1A

I came across this version on YouTube. It’s similar to my idea but much more neatly presented:-

More and More Steam Plant Information, Ideas, Design and Construction

Well, that’s enough for this page. I have plenty more Steam Plant Information, Ideas, Design and Construction already developed and just waiting to be uploaded.

Please join the Announcement list to be advised when the website has been updated, and please add your comments in the box below.

Thank you for visiting.