Photos Of 6″ Scale Little Samson Traction Engine Boilers (Plus Others) Under Construction

Yesterday, 22 May 2014, I travelled to meet Tony Baldwin of AJB Engineering to see some large scale model traction engine boilers under construction in the workshop at his home in Codnor, near Ripley in Derbyshire, UK.

Tony specialises in making steel boilers for large scale model traction engines and all the boilers are built to strict pressure vessels standards and inspected by the insurance Company RSA and on completion come complete with the CE Kitemark and all documentation.

I need the CE Kitemark for the boiler for my own 6″ scale Little Samson model traction engine because although I will build it in Thailand, I intend to export it back to the UK (after I have played with it for a while in Thailand) and sell it on. Without a boiler built and certified to the pressure vessel Standards and witnessed and certified by a company like RSA you won’t be able to sell a traction engine in Europe.

So, having placed the order for my Little Samson boiler with Tony, he kindly invited me to visit him at his home and workshop to see some boilers under construction.

First Impression Of Tony Baldwin And His Workshop

When I first entered the workshop there was a huge crackling noise. It was Tony doing some welding on a boiler. Now I have heard welding noises before – I have done plenty of welding myself – but this was almost deafening.

I was impressed – but not surprised – by the huge size of Tony’s workshops but I was surprised to see how many model traction boilers he had in hand or completed. I couldn’t count them all but there must have been around a dozen or more. And this is supposed to be a recession! It’s quite amazing what a tremendous demand there is for people wanting to own a large scale model steam traction engine in the UK.

Tony himself was equally as large in life as the workshop and the boilers and his handshake was both friendly and as strong as the steel used to make the boilers.

Recognising that Tony gave up his own time to stop working and show me around his workshops I am am truly grateful to him.

Photos Of Large Scale Model Traction Engine Boilers

Anyway enough of the talking here are some photos I took on my visit to AJB Engineering:-

One thing you’ll immediately notice is the huge size of the boilers and the thickness of the steel plate. This isn’t 3 1/2″ gauge locomotive-sized stuff with little copper boilers – this is massive. It’s not ‘model engineering’ at all really, it is real engineering to a smaller size that the original.

When I asked Edward George of Little Samson Models if the 6″ scale version had exactly the same number of components as the real one he replied (with qualifications which I’ll explain below) that yes it does. In fact so do the 3 inch and 4 inch scale versions.

You see, the drawings for all the models are copies of the original Works Drawings for the real thing. Only the dimensions are changed to suit the scale of the model in question. The exceptions are these:-

- The boiler internals are changed to suit a real life at the appropriate scale. Generally steel thicknesses are thicker that scale and smoke tubes larger but smaller in number.

- The hornplates are separate from the boiler and bolted to it. In full size practice the hornplates are part of the boiler.

Apart from that, everything on the model is an exact, but smaller, copy of the original full sized traction engine.

That’s my understanding but no doubt someone will come along – and they are welcome to do so – and offer some corrections.

More Details Of Tony’s Boiler Fabrication Workshop

Here are a few photos with some explanatory text:-

Above, as it says, is a Little Samson 6″ (equals half full-size) traction engine boiler. The diameter of the boiler barrel is 12″. (305 mm)

You can see the massive amount of welding in the foundation ring. All the welds are made using the MIG (Metal Inert Gas) process and when I asked Tony he told me that he runs welds at around 300 Amps.

Next is a photo of the plate cutting machine.

This is a machine that Tony uses to cut out the steel plate for the model traction engine boilers. It’s difficult to see from the photo but the machine is divided into two sections. On the left is the ‘input’ section. Here a drawing is laid out on the work surface and the tracing head follows the lines on the drawing.

On the right is the cutting section where an oxy-acetylene cutting torch mimics the movements of the tracing head and cuts the steel plate.

Now for a couple of photos of large scale model traction engines built and being built by Tony.

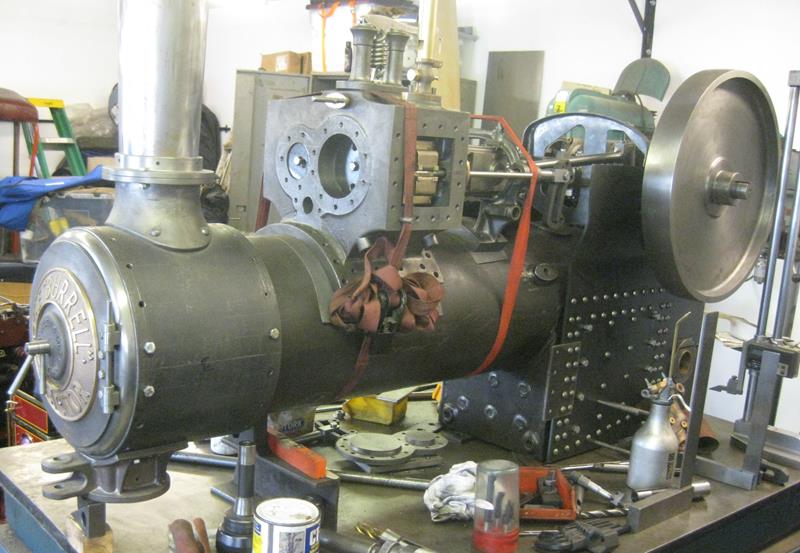

As you can see in the photo above this is a model compound traction engine. The scale is 4″ (ie 1/3rd full size) and with a boiler of 10″ diameter it is smaller than the 6″ scale Little Samson traction engine which has a boiler diameter of 12 inches. Note the fine detailing that Tony has added to this magnificent example of a large scale steam traction engine model.

Next is a photo of Burrel compound traction engine under construction by Tony.

So that’s my short report on my visit to Tony Baldwin of AJB Engineering. Tony has promised to send me some progress photos as the build of my boiler gets under way and I’ll post then here as soon as I receive them.

Im looking for a boiler for my miniature steam bulldozer project with a case traction engine I want to make something very very rare and unique because I have seen a full-size steam case bulldozer once it was at a tractor show here in Indiana once many years ago but I never once seen the bulldozer again so I thought id have 4inch scale model made if I can purchase a new boiler if someone can build a boiler for me if so please feel free to contact me 5749306228 if any one can help

Boiler for Steam Powered Bulldozer

Harrybob, what an exciting idea!

I did a search using – tracked traction engine – on Google images and all kind of wonderful machines were displayed.

One of them is the 4″ Hornsby Steam Chain Tractor built by Steve Baldock.

You can see a photo of it here:- http://modelengineeringwebsite.com/Hornsby.html

So yes, you have a good idea for as you say an interesting and unique model.

There are quite a few boiler makers in the U.K. but there is generally a long (e.g. waiting list). I had to wait 9 months for the boiler for my 6″ scale Little Samson Traction Engine model.

I can give you the names of a couple of UK boiler makers if you email me, or better, if you reply to this comment.

At 4″ scale you’ll probably need a steel boiler – particularly if it is to form the chassis for your engine as in a normal traction engine.

But before contacting a boiler maker you will need a design. It seems you are from USA (you mention Indiana) and I have no idea what the legal and insurance company requirements over there.

If you are not looking for a close scale model of the steam Case bulldozer you could maybe find an existing design that you could use.

Again I can give you a list of UK websites showing boiler designs. Please email me, or better, reply to this comment.

Hi Alan

It must have been a very enjoyable day out. Not everyone’s idea of a good day out. But I think any model maker would jump at the chance. The photographs are inspiring. I only wish my welding was as good as that on the foundation ring of the boiler. I could spend many happy hours in that workshop. Do you have any idea about the weight of your completed boiler?

I like the idea of getting it made to European standards. But I suspect that by the time you have finished the build and see a magnificent engine standing in your drive way it will be hard to send it back to UK to sell it. As it must be the one and only half size engine in the whole of Thailand if not Asia.

Hope to meet up again when you come down to pick up your container.

George

Hi George and thanks again for your valuable comments and observations.

What amazed me most of all (as I said) was how many large traction engines there were either complete or under construction.

Yes welding of that quality is something to aspire to. My welding is atrocious which I put down to not being able to see through the welding mask (plus lack of experience and skill). I bought one of those auto darkening ones (quite cheap) and it’s good to see where to strike the arc but then it goes just as dark as a normal mask.

Like you did I guess I’ll have to buy one of those electronic adjustable ones. Cromwell tools sell them.

Of course I am using arc welding (sometimes called stick welding) and Tony uses MIG welding for the boilers. I find that with arc welding on thin gauge steel running at about 70 ~ 90 Amps the weld pool is obscured by the pool of slag from the flux. mostly the arc is submerged in the slag pool so that’s another reason I can’t see what I’m doing. You don’t have this problem with MIG welding.

I haven’t tried welding thicker steel yet when I hope to be able to see the weld pool at a higher current. But as a lad I did a lot of reasonable welding on my racing car and it passed the scrutineers so it can’t have been that bad.

I do need to be able to make good quality welds – not for the traction engine the only welding there is on the boiler – but to make various tools and jigs, benches etc for the workshop.

As to the engine being to only half sized model in traction in Thailand I rather suspect it will be the only working traction engine in Thailand – or do you know of another one?

Near to our house in Pak Chong I spotted a rusting hulk of what looks like a traction engine. Just wheels and a boiler basically. When I get back I’ll take some photos of it.

Whether I’ll want to bring my half-sized traction engine back to UK to sell it (or even sell it in Thailand) is something in the far distant future – three years is my estimate from when I start making it – so we will have to wait for that time.

Yes I do hope we can find the time to visit you when we go down to Laem Chabang port to show my passport to the customs officials. But I have learned as a principle in Thailand to only try do one job in one day.

It may all go smoothly but it may take hours and hours and Kanyah doesn’t like driving in the dark. (Neither do I) Also if I have to pay a lot of money I won’t be feeling too good about it – more importantly neither will Kanyah.

I’ll let you know when we plan to go down but until after the port visit I can’t say for sure whether we will come round or not.

Keep in touch

Alan