Brilliant Idea?

Following on from the post “Disaster – Boiler Build On Hold!” above where I was struggling to fit the water tunes to the Bassett Lowke starction engine boiler I though I had a brilliant idea.

Just to recap, this was the situation then:-

I asked for help and was rewarded with what seemed like a good idea from Andrew:-

Hi Alan

Can’t you solder the pipes into the boiler shell before fitting the throat plate? Just use the throat plate loose as a template to locate their approx alignment.

Then with the pipes fixed securely in place, slide the throat plate into position on the boiler and fit the pipes in place as it slides on. The annealed pipes can be tweaked into final position and the spacing set before soldering the throat plate and the ends of the pipes

This seemed a good idea except that the tubes were a tight fir in the throatplate. I could push a tube in one at a time but there was no way I could push all five in.

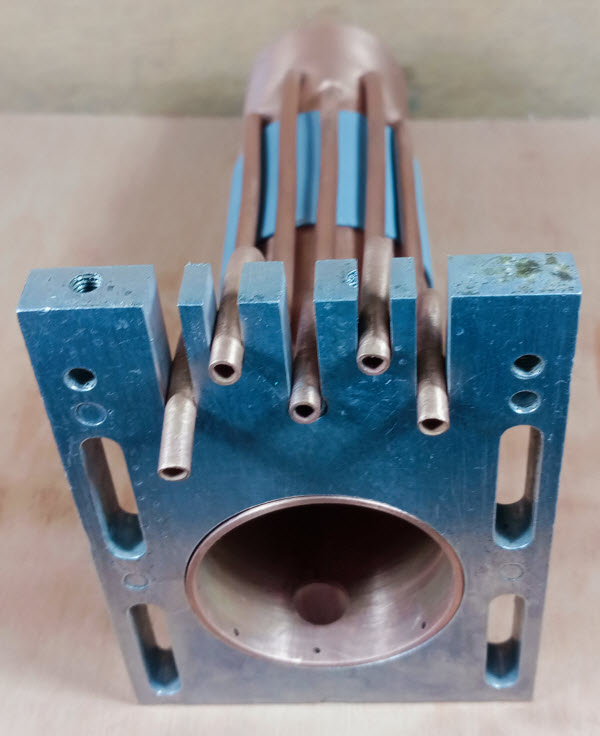

Then I had the idea to make a temporary throatplate with slots instead of holes, like this:-

The temporary throatplate was soon knocked up from a slab of aluminium and it was – not easy – but possible to get the water tunes in place.

That grey coloured plate under the water tubes is a piece of 1/16″ steel to space the tubes away from the boiler shell.

Now, I’m all ready to silver solder the tubes in place.

Using that ‘magic’ silver solder donated by George it seemed that all the gaps in the boiler around the water tubes had been filled. Looking good:-

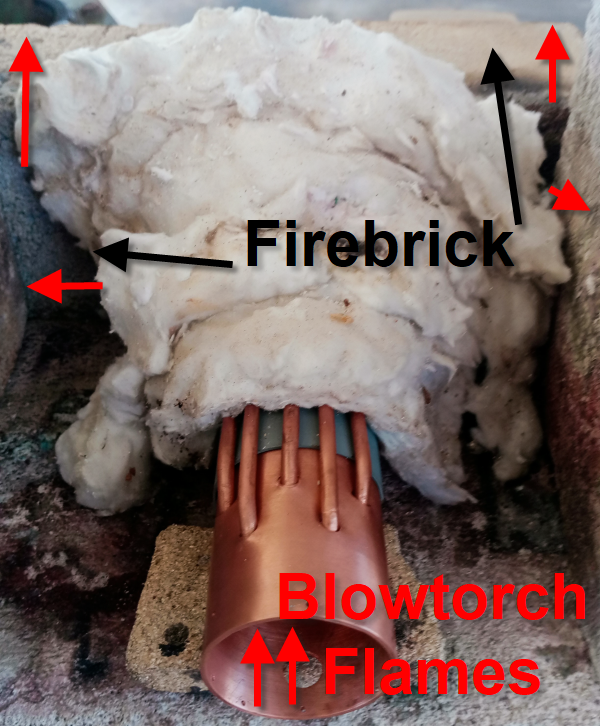

Now let’s take off the heat-protective wool from around the temporary throatplate and see what we have:-

Oh dear! That looks bad, the complete temporary aluminium throatplate has melted as has part of one water tube.

Take a closer look:-

Yikes! What a mess.

Is this recoverable? Well, I very much doubt it if for one reason only. The steel packing under the tubes is well and truly brazed to the boiler shell. Could leave it in… ? The melted water tube could be repaired but what state will the end of the boiler barrel be in after cleaning away the molten aluminium?

If not, it’s time for a new boiler and to a new design. As it happens I do have a piece of copper tube the right size for a new shell so let’s investigate further. But for now, that’s the end of this post.

PS How Did It Happen?

Take a look at the photo:-

There’s a firebrick at the far end of the boiler where the aluminium temporary throatplate was. Blames from the blowtorch reaching deep down inside the boiler hit the firebrick and spread sideways completely blasting the throatplate. The firebrick should never have been there.

Also I should have put a circular shaped firebrick inside the boiler on the far side of the water tubes being brazed. This would have prevented the flames from the blowtorch travelling down the boiler and also helped to concentrate the heat where it was needed – on the boiler inside at the point where the tubes enter the boiler.

The way to do it is have the boiler the other way round, front facing away from you. That way the throatplate is behind the torch the all heat is going towards the front of the boiler where you want it. Keep the firebrick at the end and that will throw any heat back towards the joint area.

Trick to get several tubes into a plate is to turn up some plugs that go into the ends of the tube, make the protruding part tapered and that will guide the tubes in. Even better is to make the plugs an increasing length then you put the longest one in first, then the next and so on without the risk of the previous ones popping out of place.

No need for a separate jig, just use the throatplate and pickle it along with the rest of the boiler to clean it up for subsequent soldering stages.