George’s New Big Over-Crank Type Vertical Steam Engine Model

Photo Of A Completed Benjamin Goodfellow Overcrank Steam Engine Model

NOTE: The photo of the Benjamin Goodfellow Overcrank Engine below is not built by George but by another model engineer living outside of Thailand. I am just showing it to indicate what George’s engine may look like when its finished.

About The Benjamin Goodfellow Overcrank Steam Engine Model

The new model that George is working on is a model of an over-type vertical live steam cross engine based on the Anthony Mount design.

It’s quite a bit bigger than Georges other models and will stand some 300 mm tall when complete. The flywheel will be 200 mm diameter.

George is still building the much smaller Armstrong’s Hydraulic Pumping Engine Model which has a lot of tiny parts so George alternates between the two to give some variety.

The model steam engine was designed by Anthony Mount based on an 1851 prototype discovered by Anthony Mount in what was then Brighton and Hove Engineerium which is now closed for refurbishment. Hopefully to be opened as the British Engineerium.

The original engine was installed in the cotton mill fitting shop of E & G. Hindle Ltd, Bastfield Mill, Blackburn. It was built in 1851 and was still in use in the 1950s driving the fitting shed shop when the main weaving shed engine was stopped.

A kit of castings, parts and drawings is available from Polly Models in U.K.

(Strangely the Benjamin Goodfellow Overcrank Engine is not shown on the Polly Models Website but is listed in their downloadable catalogue and price list)

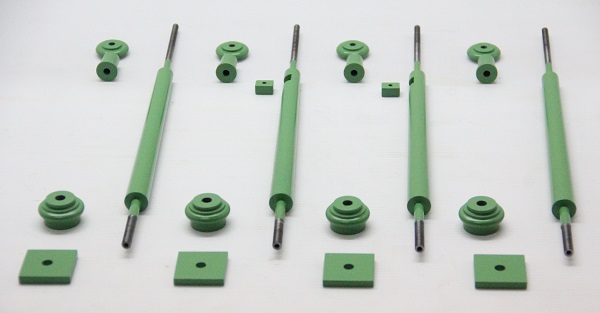

Photos Of The Parts Of The Overtype Steam Engine Model Made To Date By Thailand Model Engineer George H

Overcrank Engine Model Columns Assembled

First a photo of the engine assembled from the parts made already. Amazing high and bright finish on the flywheel – looks like chrome plating.

It’s a very handsome engine and when complete would look at home in a glass dome.

Benjamin Goodfellow ‘s Model Columns Machined

Next photo is of the columns machined. Notice that they are tapered and log and slender. Must have been a difficult machining exercise as obviously a travelling steady couldn’t be used.

1851 Overcrank Engine Steam Model Columns Painted

Now the columns are painted and shown alongside the other ornamental parts comprising the completed elegant columns.

Comments Please

Please add your comments in the box below. It adds interest for fellow model engineers and home machinists in Thailand who visit the website and shows how lively and active we all are.

That should read six inches long

George

Good afternoon Mike.

The problem I think with the term one tenth scale is a linear term. But the real scaling should be on the cube root of the volume.

As a one tenth volume of a fire box is not the same as a one tenth linear one.

As for draught the boiler I made uses the exhaust steam from the engine. It also has a separate blast nozzle.

I have also a connection that allows compress air to be used to allow the fire to be started.

The natural draught is of no use at all as the stack is only domestic inches long.

Hope that helps.

George hill.

Thanks for confirming my suspicions about the limited function of the short stack on a scale model.

As for linear scaling resulting in a cubic volumetric downsizing, I understand how that affects the combustion chamber volume,…however, since a lump of coal can burn (oxidize) only on it’s outermost surface, and not it’s entire volume, it seems that the burn-time scaling would be a linear function, yes? In other words, lets assume your lump of coal is a perfect sphere with the entire surface of the sphere being oxidized at an equal rate,…would not the oxidation process proceed along radial lines towards the center of the sphere,… at a linear rate? Further assume a 10″ radius sphere of coal burning in a full sized burner vs a 1″ radius sphere of coal burning in a 1/10 scale model burner; seems likely that the full scale “lump” of coal would last about 10 times longer than the much smaller scale model lump of coal.

But, this is all just my best guess as I have no practical experience to draw upon, so in practice, do you need to feed your burner a fresh supply of coal more frequently than a full size burner?

Watching a video on the old steam Tran firing it was little and often. About one good shovel full every two minutes.

It also stated that thirty percent of flammable components were volatile gasses that were driven off by the furnace heat. And burnt with the top air.

You mention the rate of ten inch to one inch surface area. A ten inch cube has a surface area of six hundred square inches and a one inch cube of only six square inches. And the overall temperature in a full size fire box would be constantly higher due to its size.

As they say you can’t scale nature.

I would think if I used coal sized to match the scaling I would end up using dust. That would fall through the fire bars. And At that size would not allow any draught to pass through.

I have very little experience of firing using coal but I am sure any one in a club. Back in uk could explain their experience doing so

But interesting questions raised and thought provoking.

George

You make an interesting observation in stating that as the coal heats up, various combustible gases will be driven out,…I hadn’t considered that. I’m sure that while these gases are being generated the overall BTU output will increase, but I have no knowledge as to how long the out-gassing process continues, nor what impact it has on the size & permeability of the “solid” coal lumps.

I agree with your conclusions that larger lumps of coal have larger surface areas than smaller lumps of coal, however, while the combustion of a larger surface area clearly generates more BTUs,…having a larger surface area says nothing about HOW FAST each lump is being consumed; a process which I still suspect is a linear one, as the coal is consumed from it’s outermost surface and progresses linearly towards the center.

I’m curious, is the burn-time of the coal also scaled down to a similar fraction as the scaling of the entire engine,…ie 1/10th scale engine results in fuel being consumed in roughly 1/10th the time of the full scale engine? I’m also curious as to how much “drafting” is produced by a scaled down smoke stack; is the induced air flow through the burner (generated by hot air rising up through the smoke stack) adequate for proper & complete combustion or do you need to force air into the burner with a fan?

Good morning Mike

The boiler is finished and runs well on Welsh steam coal.

Alan kindly sent me some down to see the boiler would perform.

Initially I tested it on charcoal. It will steam ok. But you have to keep on feeding the fire all the time.

Which can lead to a reduced steaming rate.

You can buy a gas burner for it from GLR.

I have since had coal delivered from UK.

Cost fifteen pounds to buy about one hundred and thirty to get it here.

But worth it.

I will send Alan some pictures of the boiler build.

He might post them on the web site.

Happy New Year to all

George

Lookin’ good so far George. It always amazes me at how nicely most engines and their respective parts scale down in size so easily. I’m quite interested to see the boiler parts and learn what fuel(s) you plan to burn. It’s my understanding that many of these original steam engines burned either coal or wood, which doesn’t seem like it would scale down very well ? Do modelers switch to a liquid fuel instead,…or perhaps propane??