Making A Mockup Of The Boiler

The Bassett Lowke design drawings for the Burrell traction engine boiler published in 1950 allow for a cast ‘downcomer’ to form a wet Backhead.

Since castings are now not available (75 years later!) I can choose between having a casting made, carving from a solid block of bronze or fabricating from copper sheet.

I chose the latter option. But I could see from the drawings that flanging the various copper sheets and fitting to the boiler may not be as simple as it appeared to be in my CAD drawing.

So I decided to spend a bit of time making a mock-up of the boiler and the back-end plates including the Throatplate and Backhead.

The parts were made simply and quickly from thin plywood and cardboard. Here are the parts for the boiler Throatplate and Backhead (called the Downcomer on the Bassett Lowke drawings):-

Note that the plate on the left – the Backhead will be formed in one piece by flanging the upstand around the perimeter.

Also, note that the piece on the right – the Throatplate will most likely also be provided with flang(es) depending upon decisions made after the mockup is completed.

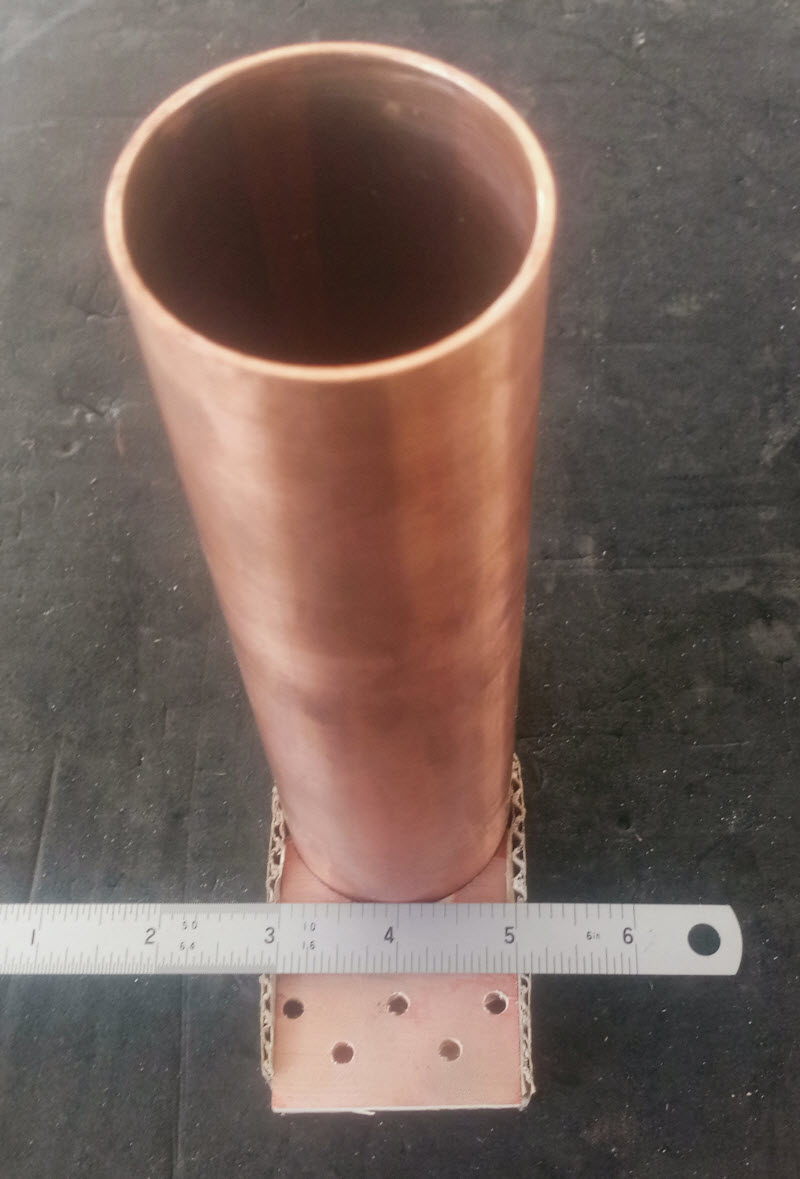

The next photo shows the boiler Throatplate and Backhead parts assembled together with the boiler.

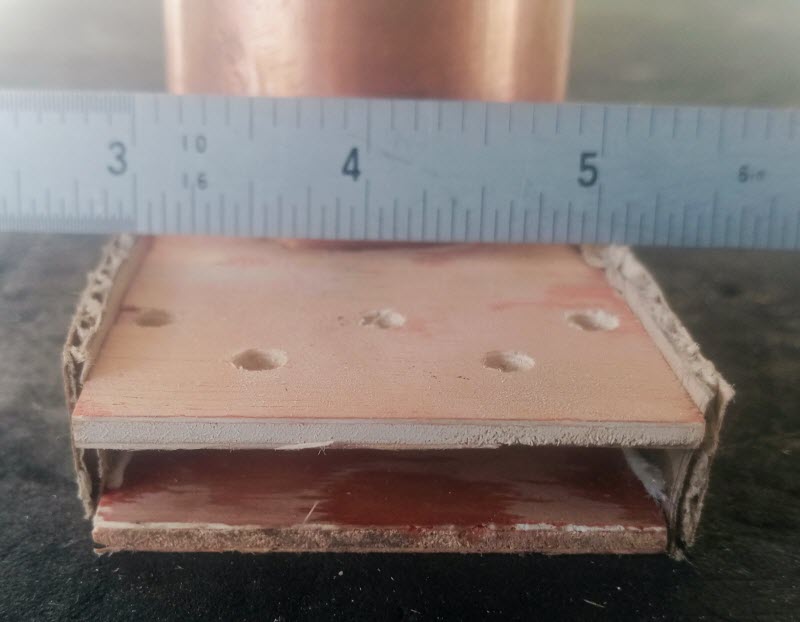

And the next photo shows the detail of the wet Backhead or Downcomer.

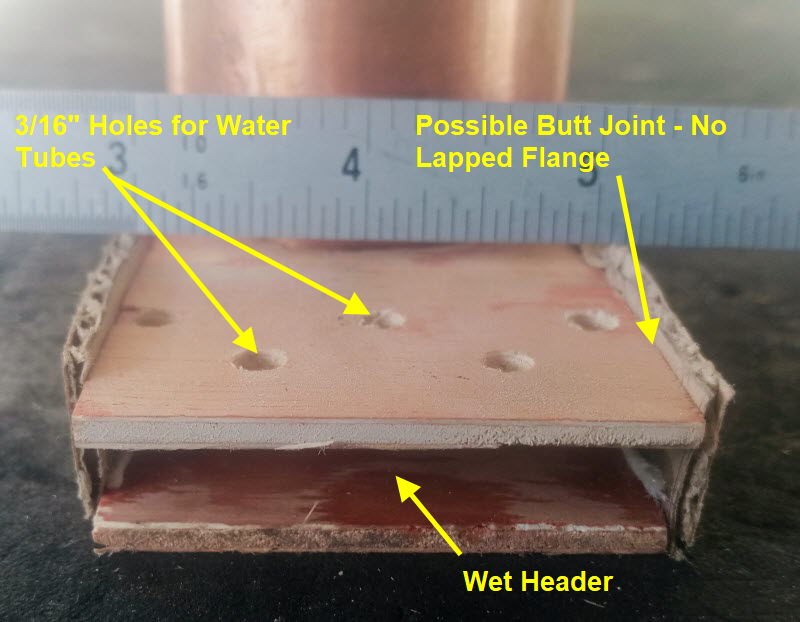

The next photo is identical but it’s marked up with a few notes.

This as a very useful exercise. One of the things I wanted to check is whether the Throatplate could be flanged or not. If you look at the photo you will see that there are two holes for Water Tubes right next to the flanges of the Wet Header – certainly not enough room to allow the Throatplate to be flanged.