Mikes DIY CNC Slant Bed Lathe Part 05 D1-4 Cams, Studs, Tailstock

D1-4 Cams & Studs Needed For Spindle And Chuck Adapter Plate

| 3 cams needed used in D1-4 spindle nose. 3 studs needed for chuck mounting.Purchased from: Mac-it Corporation Lancaster, PA 17602 US jzymnis @ macit.comST55708 #4 CAM STUD ($10.80) 3 – $32.40 ST55608 #4 CAM ($18.96) 3 – $56.88 |

Turning a Magnesium Billet

Gas Lifter For The Lid

| Gas lifter for the lid; Rough size: 8” closed, 14” open.

Purchased 200Nm model via Lazada for ~ $10. |

| Belt tensioner pulley from local auto parts store: 450 Bht ~ $12.50

Haven’t needed to use the tensioner as yet (25May2016) |

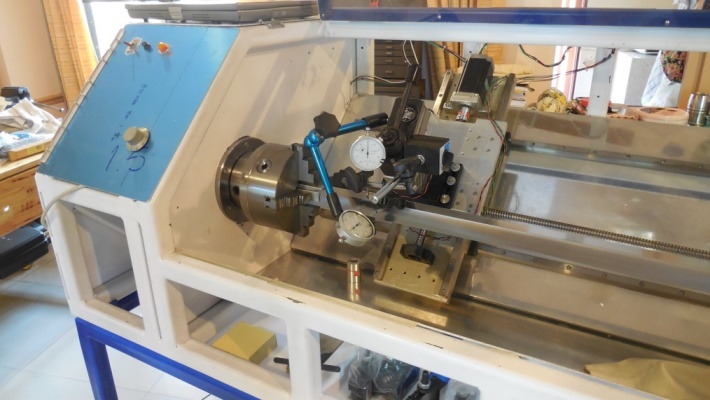

CNC Lathe Slant Bed Alignment

Materials And Preparation

25mm x 25mm x 1M square steel bar for alignment. Bought from machine shop

800 Bhat ~ $22

Mounted steel bar into 4-jaw scroll chuck & spent much of the day aligning the bed,…several bolt holes needed to be enlarged with Dermal & carbide rotary file.

Bed Alignment Procedure

1. Place into chuck a known straight square or round rod whose length extends to tailstock.

2. Use 2 dial gauges: one gauge reads X axis travel, one gauge reads perpendicular to X axis.

3. Loosen all 10 bolts which fasten bed to frame.

4. Run the Z carriage end to end, taking time to adjust tilt & yaw of the bed to best tolerance.

5. Tighten all 10 bolts starting closest to chuck end, taking care not to move the bed out of alignment during this phase.

6. Loosen all cap screws holding Z rails in place.

7. Using only X axis dial gauge, move rails up or down to achieve +/- 0.001” tolerance of Z motion end to end.

8. Starting at chuck end, Tighten all cap screws while not moving X axis out of tolerance.

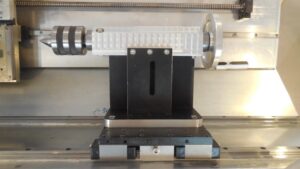

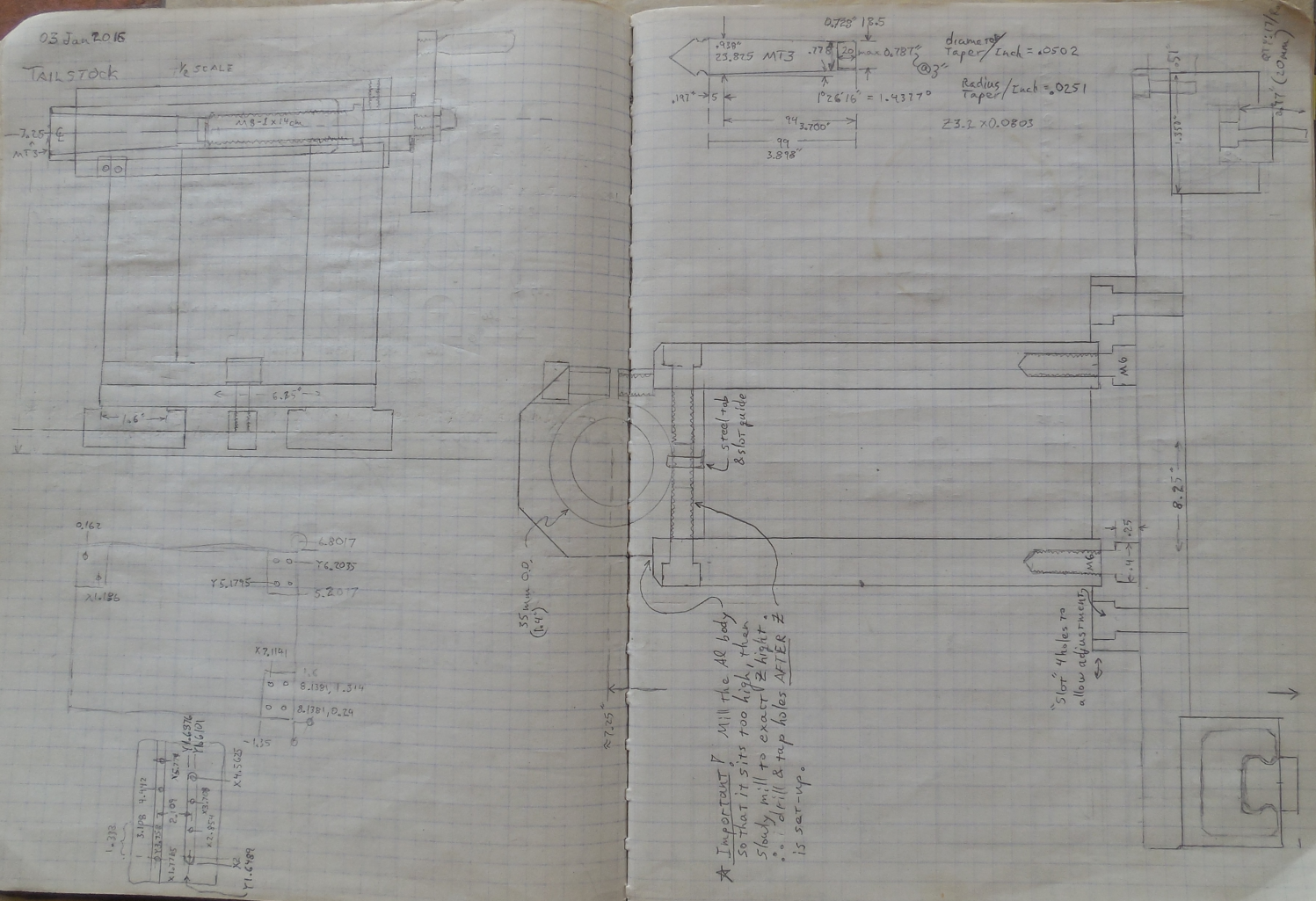

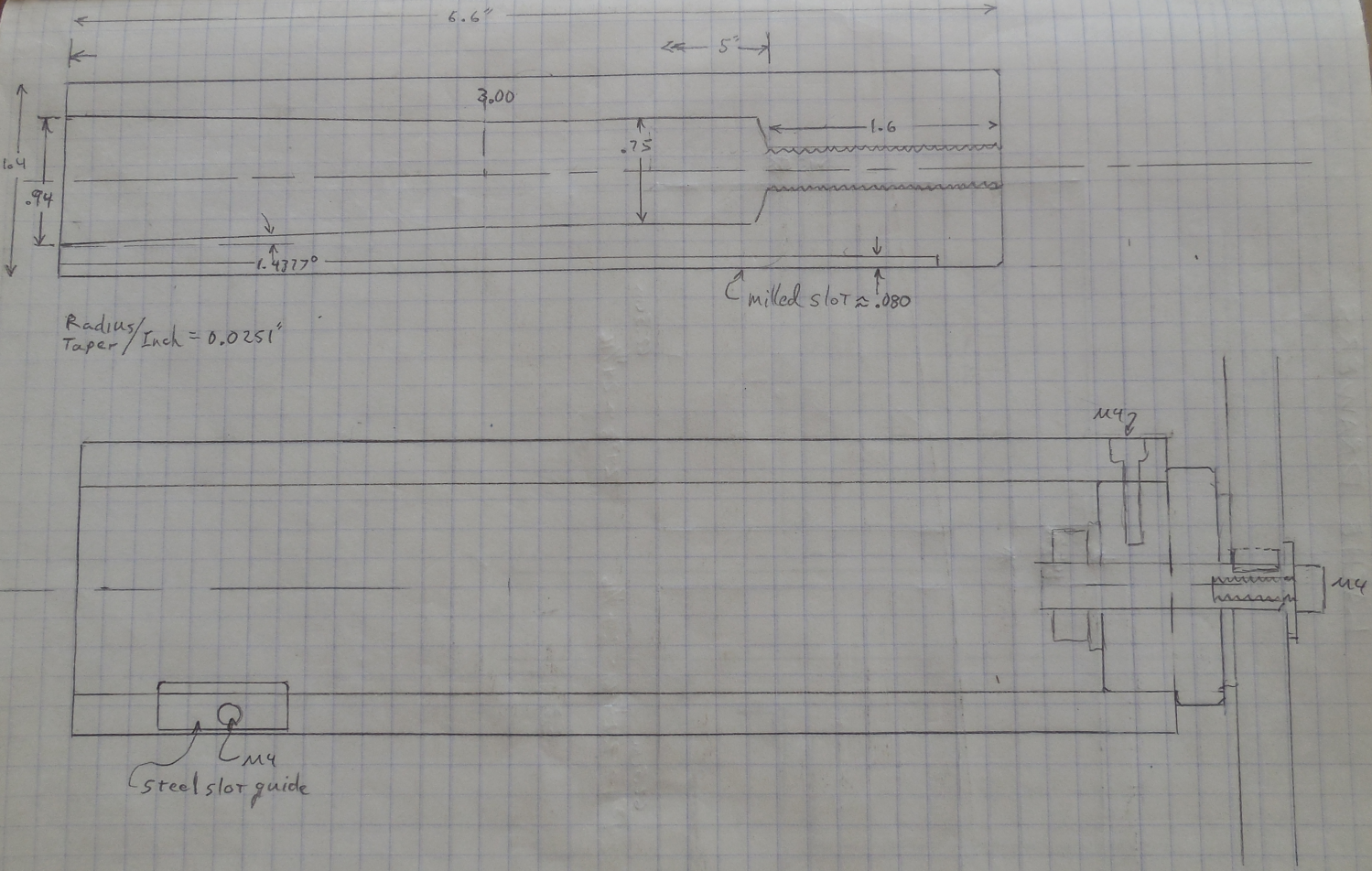

Tailstock Assembly

Mounted on a separate set of Linear Rails & bearing blocks.

- Tailstock Rails: 2 DFH15, 1000 MM long and 4 linear bearings, DFH15B.

- One Handle turn = 1mm linear movement.

- Barrel made from cold rolled mild steel using this lathe.

Tailstock Design Sketches

That concludes this section of the DIY CNC Slant Bed Lathe build Part 05

Future Pages

We’ve now covered 13 out of 16 topics!

Next section will be about the Electronics

Other Pages In This Section