I Crashed The Work Into A Milling Cutter At High Speed ~ The Aclass Power Table Feed Stopped Working

Bridgeport Owners – This Could Well Apply To Your Milling Machine

The Argo 3VH Milling Machine is a close clone of the renowned and ubiquitous Bridgeport milling machine.

Even the electricals seem to have been copied closely so if you have this problem on your Bridgeport this may the answer for you.

The Power Feed Unit Not Working Issue On My Argo 3VH Milling Machine

The milling table power feed on my Argo 3VH milling machine is a great time and effort saver.

It has forward, reverse and jog controls and the speed is variable via a little pot on the unit.

At high speed it rotates the mill table feedscrew faster then you could turn it by hand. A great time saver.

The about two weeks ago I switched on the fast feed – in the wrong direction! The workpiece on the mill table smacked into the milling cutter which was an inch in diameter so it didn’t suffer any damage.

But after that the power feed unit refused to work.

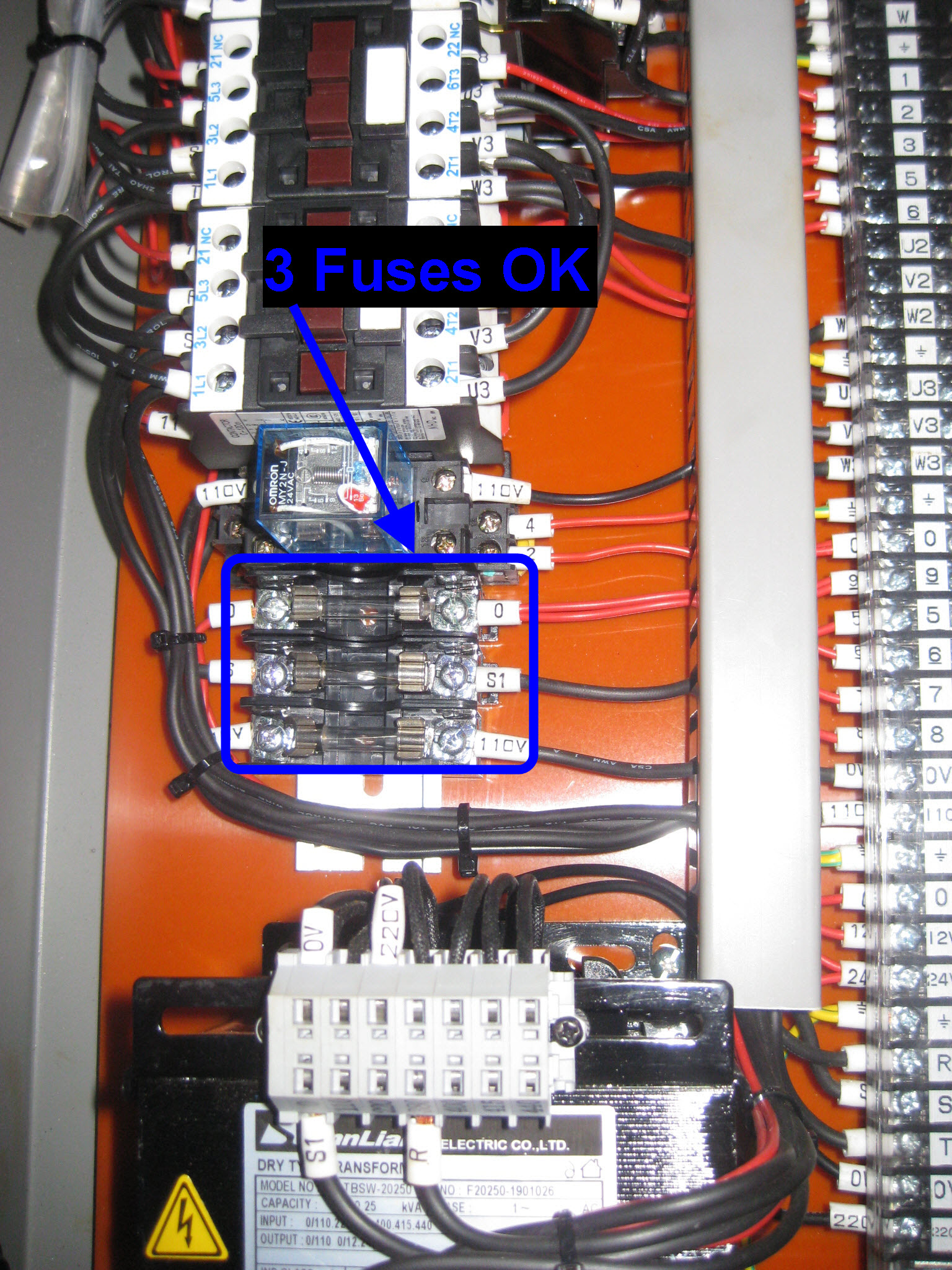

I did a bit of investigation, including checking those fuses that had caused a complete loss of power to the mill and as described on the xyz page.

These fuses seemed OK and the led in the switch on the power unit was on so it seemed not to be a power problem.

I sent an email to the distributor as below:-

| Hello,If this message can get to Joe please?Hi Joe you were helpful when I had a power problem with the Argo mill I bought from John Barton.Can you please help with another issue?I accidentally turned to fast feed in the wrong direction and the workpiece on the table hit the (big) endmill.The table feed stopped immediately but now it won’t work.I have checked the three fuses inside the control panel and they are OK. Also the red light is on on the motor feed unit. (See photos)Is there anything else I can check? Thank you andChok Dii Khrap, Good LuckAlan and Kanyah Brown |

These are the photos I was referring to:-

The first photo is a close-up of the power feed unit.

You can see the Speed-Adjust pot. Note it is set to 3. (I’ll come back to this later)

Also you can see that the off/on switch light is on – clearly the unit is getting power.

You can’t see it in this photo but just to the right of the illuminated power switch is a title that says “RESET”. I’ll come back to this later, too.

The next photo is of the inside of the control panel showing the three 110 V fuses.

You can probably see in the next photo that those three 110 V fuses are all good. I didn’t rely on a visual inspection – they all tested OK with an Ohmmeter.

The next photo shows the ‘RESET’ text I mentioned earlier and I was expecting there to be a reset button of some description around there.

After a lot of searching and prodding i found nothing resembling a reset button.

Response From The Distributor

By this time I had received an email from the distributor and the email and my reply is shown below:-

| Dear Mr.Alan,We are not sure where is the problem, maybe you can send the total set to my office:

FORCE LINK CO.,LTD 120/39 MOO 12 Kingkaew Rd., Rachatewa, Bangklee Samutprakarn 10540 Tel: 02-7500005,7502305 Or you can buy one new power feed, the price is Baht 9,000.00 (include freight charge). The old one can be spare part. If there is anything unclear, please call me 081-4984715 Thanks Joe |

A helpful response but it didn’t solve my problem. I wasn’t convinced that the problem lay with the power unit itself – there may be an electrical fault as yet undiscovered.

For example I wanted to make sure that the limit switch wasn’t holding off the power to the motor.

But the cost of the replacement unit looked reasonable so I replied as follows:-

| to ZhouJoe many thanks for your very quick reply

.Your offer of a new one is very reasonable. I am thinking about what to do. I want to make sure that I can disconnect the electrical power supply properly and safely without causing any damage, then I’ll let you know.. |

APF 500 Aclass Power Table Feed Unit Information From The Internet

Having drawn a blank so far I started an internet search for information on the power feed unit.

There was no information on the distributor of the Argo mill’s website so it was detective work again.

The key was found in the letters APF 500 and word Aclass I noticed on the power feed unit and which you can see on the photos.

I added ‘Bridgeport’ to the search string since Bridgeport machines are often fitted or retro-fitted with this kind of power feed unit.

“Bridgeport APF 500 Aclass Power Table Feed unit” brought plenty of search results many of them for units for sale on eBay.

On one of these sales pitches there was a phrase that encouraged me:-

-

When rapid feed initiated (Red button), plastic gear and electronic components will not be damaged IF BY ACCIDENT tooling crashes the workpiece.

Then I Found An Instruction Manual From The Manufacturers Of The APF-500 Aclass Power Feed Unit.

Yes, I had struck gold – but like gold it took a lot of searching for. If fact I have tried to find the same search string that I used to locate the Manual but having spent more than an hour can’t locate the download page again. I think that the phrase “AClass” must be an important search term.

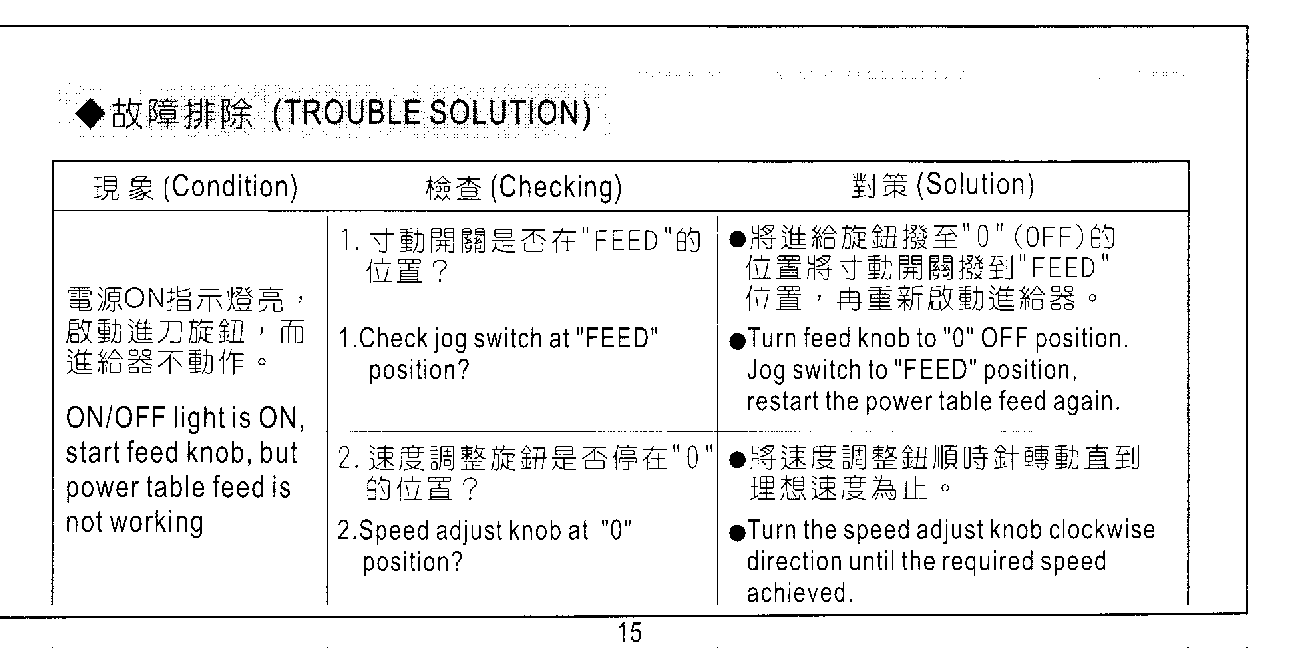

And right there in the troubleshooting section of the Aclass Power Table Feed Installation & Operation Manual lay the answer. Here is an extract from the manual identifying my exact problem an the solution:-

If the unit is not working (one of several possibilities):-

“Turn the Speed Adjust knob to zero and the On/Toggle switch to zero.”

It worked!

Remember I mentioned above about the Speed Adjust pot being on three? That is why the unit didn’t work after the crash.

So simple, But the distributor had no idea!

Download The APF-500 Aclass Power Table Feed Installation & Operation Manual As A .Pdf File Here

If you have been looking for instructions for the APF-500 Aclass power table feed unit or have experienced the same issues with the unit not working that I have, then you can freely download the manufacturer’s installation & operation manual with the trouble-shooting guide here. It will save you one heck of a lot of searching in the internet to find the original download page.

Leave a Reply

You must be logged in to post a comment.